|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 5-4210-233-14&P-1

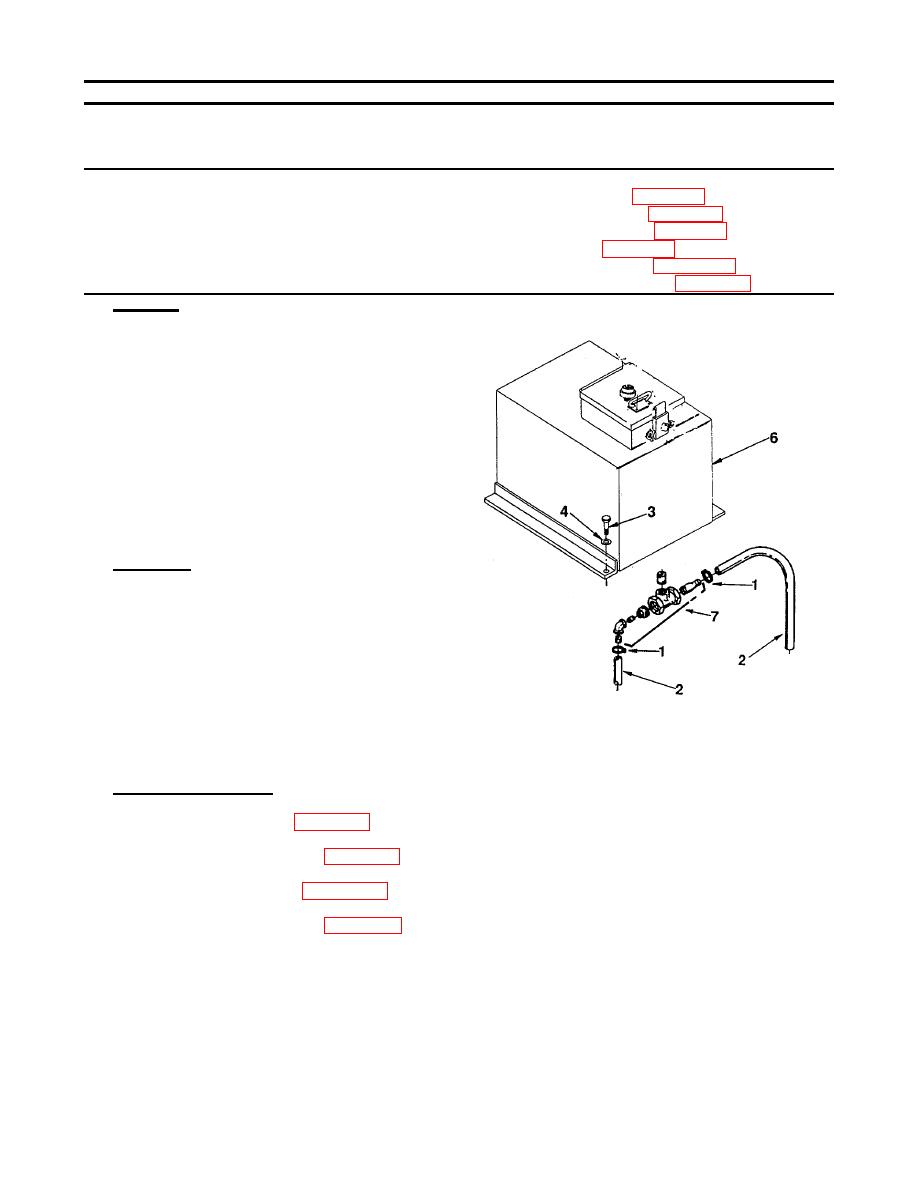

5-8. FOAM TANK ASSEMBLY

This task covers:

a. Removal

c. Follow-on Maintenance

b. Installation

TOOLS REQUIRED

EQUIPMENT CONDITION

Tool Kit, General Mechanics, Automotive

Raise Aerial Ladder (see para 2-14.)

(Appendix B, Section III, Item 1)

Foam System Drained (see para 2-17.)

Main Engine Shutdown (see para 2-12.)

MATERIALS/PARTS REQUIRED

APU Shutdown (see para 2-16.)

Pipe Sealant (Item 2, Appendix E)

Batteries Disconnected (see para 4-114.)

Curb Side Panel Removed (see para 4-26.)

a. Removal.

(1)

Loosen two hose clamps (1) and remove

two hoses (2).

(2)

Remove cargo floor grating by removing

four screws. Set grating aside.

(3)

Remove four bolts (3) and four washers (4).

(4)

Remove foam tank (6)j

(5)

If replacing tank, remove pipe fittings from

bottom of tank.

b. Installation.

(1)

Install two hoses (2) and secure with two

clamps (1).

(2)

If necessary, apply pipe sealant (Item 2,

Appendix E) to pipe threads and install pipe

fittings (7) on new foam tank.

(3)

Position foam tank (6) and secure with four bolts (3) and washers (4).

(4)

Position floor grating and secure with four screws.

c.

Follow-On Maintenance.

(1)

Fill foam system (see para 2-17).

(2)

Install curbside panel (see para 4-26).

(3)

Connect batteries (see para 4-114).

(4)

Aerial ladder bedded (see para 2-14).

5-34

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |