|

| |

TM 5-4210-230-14&P-1

TRUCK SERVICE MANUAL

STEERING

The pressure unbalance then causes the valve to

compress the spring (10) allowing the major portion of the oil

to bypass into the intake chamber (from 3 to 6) in the same

manner as is accomplished by flow controlling. Relief

pressures are usually between 5170 and 9995 kilopascals

(750 and 1450 PSI) depending on the vehicle requirements.

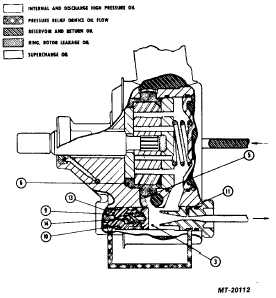

Fig. 6 Pressure Relief

MAINTENANCE

FLUID LEVEL

1.

Run engine until power steering fluid reaches normal

operating temperature, approximately 80°C (170°F),

then shut engine off. Remove reservoir filler cap and

check oil level.

2.

If oil level is low, add power steering fluid to proper

level and replace filler cap. For lubrication intervals

refer to operator's manual. For types of lubricant

recommended refer to Lubrication Section CTS-2412.

3.

When checking fluid level after the steering system has

been serviced, air must be bled from the system.

Proceed as follows:

a.

With wheels turned all the way to the left, add power

steering fluid to level indicated on reservoir.

b.

Start engine, and running at fast idle, recheck fluid

level. Add fluid if necessary.

c.

Bleed system by turning wheels from side to side

without hitting stops. Maintain fluid level just above

internal pump casting. Fluid with air in it will have a

light tan or milky appearance. This air must be

eliminated from fluid before normal steering action

can be obtained.

d.

Return wheels to center position and continue to run

engine for two or three minutes, then shut engine

off.

e.

Road-test vehicle to make sure steering functions

normally and is free from noise.

f.

Recheck fluid level as described insteps 1 and 2.

BELT TENSION

A belt that has been previously tensioned is considered to

be a used belt and should be tightened to from 245 to 311

Newtons (55 to 70 lbs.) A belt that has never been tensioned

is considered to be a new belt and should be tightened to 445

Newtons (100 lbs.).

Place Belt Tension Gage SE-2312 or equivalent, midway

between the pulleys on drive belt being checked.

BELT ADJUSTMENT

When adjusting a power steering pump belt, never pry

against the pump reservoir or pull against the filler neck. To

increase belt tension move the pump outward by prying

against the bracket pry lugs or against the pump housing

casting extension directly behind the pump drive pulley.

1.

When power steering pump is driven by a single belt:

a.

Loosen the pump attaching bolts and adjust the belt

to correct tension by moving the pump outward,

away from the engine.

b.

Snug all pump mounting bolts and remove pry bar.

c.

Tighten all pump mounting bolts to specified torque.

d.

Check belt tension.

2.

When the power steering pump is driven by two belts in

a matched set:

a.

Follow same checking and adjusting procedure as 1

above, but if it is necessary to replace one belt, both

must be replaced by a new matched set to equalize

belt tension in both belts. Check tension in both

belts.

3.

When the power steering pump pulley is driven by one

primary belt and is used as an idler for a second belt

driving some other accessory:

CTS-2296R Chapter 1, Page 5

PRINTED IN UNITED STATES OF AMERICA

|