|

| |

TRUCK SERVICE MANUAl

TM5-4210-230-14&P-1

STEERING

DESCRIPTION

The housing and internal parts of the pump are

inside the reservoir so that the pump parts operate submerged

in oil. The reservoir is sealed against the pump housing,

leaving the housing face and the shaft hub exposed. The

reservoir has a filler neck fitted with a cap. On the 125 series

pump, a shaft bushing and seal are pressed into the housing

from the front. The drive shaft is inserted through this seal

and bushing. On the 235 series pump, the shaft is supported

in the front with a ball bearing and in the back with a needle

bearing. The drive shaft seal is pressed into the housing and

located behind the ball bearing. A large hole in the rear of the

housing contains the functional parts; namely ring, rotor,

vanes and plates. A smaller hole contains the control valve

assembly and spring.

The thrust plate (Figs. 1 & 2) is located on the inner

face of the housing by two dowel pins. This plate has four

central blind cavities for undervane oil pressure. The two

outer blind cavities direct discharge oil through the two cross-

over holes in the pump ring (Fig. 3), through the pressure

place and into cavity 1 (Fig. 4). The two outside indentations

in the thrust plate are for intake of the oil from the suction part

of the pump.

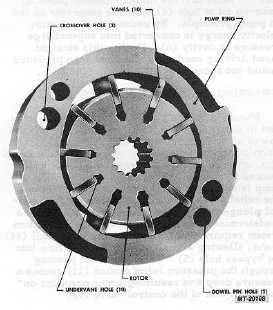

The pump ring (Fig. 3) is a plate having the mating

surfaces ground flat and parallel. The center hole is a two-

lobed cam in which the rotor and vanes operate. The ring is

placed next to the thrust plate and located with the same

dowel pins.

Fig. 3 Pump Ring and Rotor

The pressure plate is fitted against the ring and

located with the same two dowel pins. This plate has six

through ports. The four central through ports connect from

cavity 1 (Fig. 4) to supply undervane oil pressure. The two

outer ports pass oil under discharge pressure to cavity 1. The

two indentations are for oil intake from the suction part of the

pump, cavity 6 (Fig. 5) into the rotor.

The reservoir is for oil storage. It receives and

directs the return oil back to the make-up passage of the

pump.

The drive shaft is fitted with a pulley and is belt

driven from the crankshaft. The rotor is loosely splined to the

drive shaft and secured with a retaining ring. It is located

centrally within the ring and between the thrust and pressure

plates. The ten vanes are mounted in radial slots in the rotor

(Fig. 3).

OPERATION

The mode of operation of the power steering pump is

based upon the demand of the power steering system. The

various major modes of operation are: slow cornering,

moderate to high speed straight ahead driving, and cornering

against the wheel stop. The pump is designed to recognize

these conditions as required by the steering gear valve and

compensate for them internally.

As the drive shaft turns the rotor, the vane tips follow

the inner cam surface of the pump ring, moving outward and

inward twice during each revolution. This results in a

complete pumping cycle every 180 degrees of rotation (Fig.

3). Oil is moved in the spaces between the vanes. As the

vane tips move outward, oil is sucked into the inter-vane

spaces through four suction ports in the pressure and thrust

plates. The pressure of the oil is raised, and the oil is

discharged from the pump ring, as the vane tips move inward.

High pressure oil discharges into cavity 1, (Fig. 4), through

two open ports in the pressure plate, and through two blind

ports in the thrust plate, which are connected to cavity 1 by

the cross-over holes in the ring. A portion of this oil is

circulated through the central port system in the pressure

plate, forcing the vanes to follow the cam surface of the ring.

The ring-rotor leakage oil 12 (Fig. 4) is used for bushing

lubrication and then bled to the reservoir.

SLOW CORNERING (FIG. 4)

During slow cornering maneuvers, the oil pressure

required will usually not exceed 2760 kilopascals (400 PSI)

RPM of the pump is not high enough to require internal

bypassing of oil; therefore, the pump bypass port to (5)

remains closed.

CTS-2296R Chapter 1, Page 3

PRINTED IN UNITED STATES OF AMERICA

|