|

| |

TRUCK SERVICE MANUAL

TM 5-4210-230-14&P-1

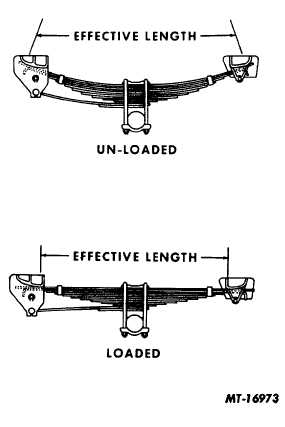

As the spring assembly deflects these leaves come in

contact providing increased capacity and stiffness.

Fig. 5 Progressive Spring Assembly

MAINTENANCE

Lubrication

For lubrication intervals, refer to Operator's

Manual. For types of lubricants recommended, refer to

LUBRICATION, Section CTS-2412.

SERVICING

Although the exact servicing procedures are

different for each type of spring assembly and spring

assembly application, the basic procedures are similar.

The following is a general outline for servicing all spring

assemblies.

Removal

1.

Place floor jack under truck frame and raise truck

sufficiently to relieve weight from spring to be

removed.

2.

Remove shock absorbers where used.

3.

Remover U-bolts, spring bumper and

retainer or U-bolt seat.

4.

Remove

lubricators

(not

used

on

springs equipped with rubber bushings).

5.

Remove nuts from spring shackle pins

or bracket pins.

6.

Slide spring off bracket pin and shackle pin.

7.

If spring is rubber bushed, bushing halves may be

removed from each side of spring and shackle

eye.

Installation

Before reassembly, all shackle bolts, U-bolts, etc.

should be cleaned and lubricated for proper installation.

While the actual installation procedures will vary

with each spring type, the pivot end of spring is usually

fastened to frame bracket first. Shackle end can then

be fastened by aligning shackle to other frame bracket.

When installing U-bolts for securing axles, do not final

tighten until springs have been placed under normal

load. See TORQUE CHART for U-bolt torque

specifications. Spring failures may occur at the center

bolt hole if U-bolts become loosened. These bolts must

be kept tight and checked frequently. Spring pins should

also be checked periodically.

Disassembly

1.

Clamp spring end in vise and remove old bushing

from spring eye.

2.

Reposition spring in vise so that assembly will be

clamped near center.

3.

If bolted type rebound clips are used, remove

nuts, bolts and spacers; where clinch type

rebound clips are used, bend tabs of clips up,

being careful not to break them. Heating clips with

torch will help avoid breakage.

4.

Remove nut from spring center bolt.

CTS-2680S Chapter I Page 4

PRINTED IN UNITED STATES OF AMERICA

|