|

| |

TRUCK SERVICE MANUAL

TM 5-4210-230-14&P-1

SPRING ASSEMBLIES

DESCRIPTION

Constant Rate

Constant

rate

springs

are

leaf-type

spring

assemblies that have a constant rate of deflection. For

example, if 227 Kg (500 lbs.) deflect the spring

assembly 2.54 cm (1 in.), then 454 Kg (1000 lbs.) would

deflect the same spring assembly 5.08 cm (2 in.). Thus,

the rate of deflection is constant.

Constant rate springs are mounted to the axle with

U-bolts, nuts and lock washers. The front end of the

spring is mounted to a stationary bracket while the rear

end of the spring is mounted to a spring shackle. The

shackle allows for variations in spring length during

compression and rebound of the spring.

This type of spring assembly is used in both front

and rear axle applications on IH vehicles.

Figs. 1 and 2 show typical views of constant rate spring

assembly applications.

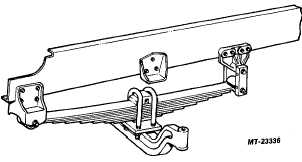

Fig. 1 Front Axle Application (Constant Rate)

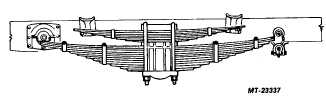

Fig. 2 Rear Axle Application (Constant Rate)

Taper Leaf

Taper leaf springs are leaf type spring assemblies that

have spring leafs which are thicker in the center than the

ends. This design results in a fewer number of leafs

which provides lighter weight and softer ride due to

lower inner leaf friction.

Taper leaf springs are mounted to the axle with U-

bolts, nuts and lock washers. The front end of the

spring is mounted to a stationary bracket while the rear

end of the spring is mounted to a spring shackle. The

shackle allows for variations in spring length during

compression and rebound of the spring.

Taper leaf spring assemblies are used on front

axles only. Figure 3 illustrates a Taper leaf assembly.

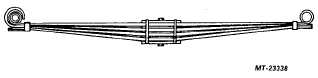

Fig. 3 Taper Leaf Spring Assembly

Auxiliary Springs

Auxiliary springs are leaf-type spring assemblies

usually mounted on top of the vehicle rear spring

assemblies. Auxiliary springs are only used when the

vehicle is under heavy load. The auxiliary spring

assumes part of the load by contacting special brackets

attached to frame rail slides when the load is sufficient

to compress the vehicle rear spring assemblies to the

point of contact.

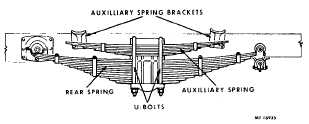

Fig. 4 illustrates an auxiliary spring assembly.

Fig.4 Auxiliary Spring Assembly

Progressive (Vari-Rate)

Progressive (Vari-rate) springs are leaftype spring

assemblies with a variable deflection rate obtained by

varying the effective length of the spring assembly.

This is accomplished by using a cam-type bracket. As

the spring assembly deflects, the point of contact on the

bracket moves toward the center of the spring assembly

shortening the effective length, Figure 5.

Vari-rate spring assemblies also incorporate a

progressive feature in that the bottom spring leaves are

separated at the ends.

CTS-2680S Chapter I Page 3

PRINTED IN UNITED STATES OF AMERICA

|