|

| |

TRUCK SERVICE MANUAL

TM 5-4210-230-14&P-1

PROPELLER SHAFT

SERVICE INSTRUCTIONS

DISASSEMBLING UNIVERSAL JOINT

1.

SNAP RING Remove by pinching the ends together

with a pair of pliers. If a ring does not readily snap

out of the groove in the yoke, tap the end of the

bearing cap lightly to relieve the pressure against the

ring (Fig. 24).

2.

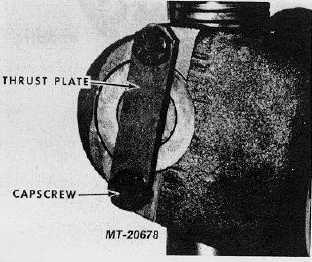

THRUST

PLATE

CONSTRUCTION

(Fig.

25)

Remove capscrews and plate. The balance of, the

disassembly and assembly instructions are the same

as those for snap ring joints.

3.

NEEDLE BEARING CAP Remove by driving on the

end of one bearing cap until the opposite bearing cap

comes out. Turn the joint over and tap the exposed

end of the journal cross until the opposite needle

bearing cap is free. Use a soft round drift with flat

face about .79 mm .(1/32") smaller than the hole

diameter in the yoke, otherwise, there is danger of

damaging the bearing.

Fig. 24

Fig. 25

4.

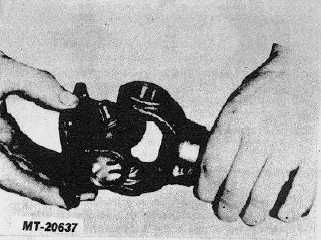

JOURNAL CROSS -Remove by sliding it to the side

of the yoke and tilting it over the top of the yoke lug

(Fig. 26).

Fig. 26

ASSEMBLING UNIVERSAL JOINT

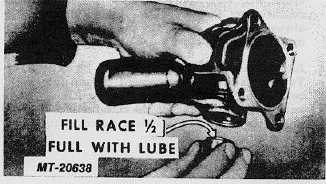

Reassembly is merely reverse order of the above

operations. On joints without a lubrication fitting, repack

reservoirs in the journal cross ends with the recommended

lubricant. Make sure the reservoir in each trunnion is filled.

With the rollers in the race, fill the race about 1/2 full (Fig.

27).

Fig. 27

U-BOLT CONSTRUCTION

U-Bolt joints are a combination of U-Bolt and snap

ring construction (Fig. 28). Except that the U-Bolts are

disassembled when the complete propeller shaft is removed

from the vehicle, the balance of disassembly and assembly

instructions are the same as those for snap ring joints.

CTS-2730 Page 15

PRINTED IN UNITED STATES OF AMERICA

|