|

| |

TRUCK SERVICE MANUAL

TM 5-4210-230-14&P-1

PROPELLER SHAFT

SERVICE INSTRUCTIONS

Needle bearing joints are simple in construction, easily

removed from the vehicle and readily disassembled and

reassembled without the use of any special tools or any

special mechanical knowledge.

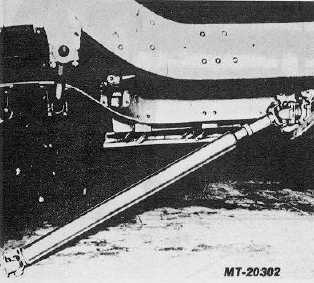

Fig. 13

REMOVAL FROM THE VEHICLE

1.

Double Flange, Yoke Types (Bearing Cap and Snap

Ring Construction)(Fig. 13)

All Double Flange Yoke Type Joints are removed as a

complete assembly by removal of the Companion Flange

Bolts, Nuts and Lockwashers, which allows the assembly to

slip out from between the Companion Flanges.

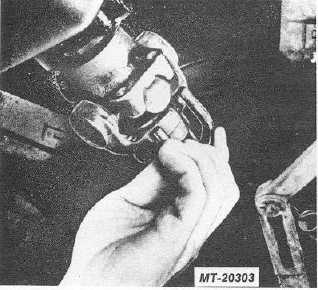

Fig. 14

2.

Double End, Yoke Type (U-Bolt (Construction) (Fig.

14)

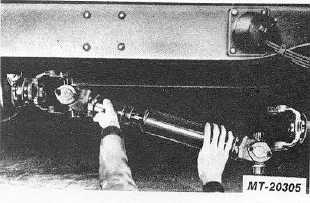

Fig. 15

Remove the U-Bolts, Nuts, and Lockwashers from

the End Yokes. Slide the Sleeve Yoke toward the shaft to free

the Bearings from their seats between the shoulders in the

End Yokes (Fig. 15). Care should be taken not to drop the

two Bearings from the trunnion ends of the Journal Cross at

both ends of the driveshaft. The End Yokes remain on the

vehicle.

Fig. 16

3.

Double End Yoke Type (Bearing Cap Construction)

(Fig. 16)

Remove the capscrews, lock plates and bearing and

retaining cap sub-assemblies, from the transmission and axle

end yokes. Remove the driveshaft with the remaining journal

crosses and bearings as a unit. The end yokes remain on the

vehicle.

CTS-2730 Page 12

PRINTED IN UNITED STATES OF AMERICA

|