|

| |

TRUCK SERVICE MANUAL

TM 5-4210-230-14&P-1

INSTRUMENTS

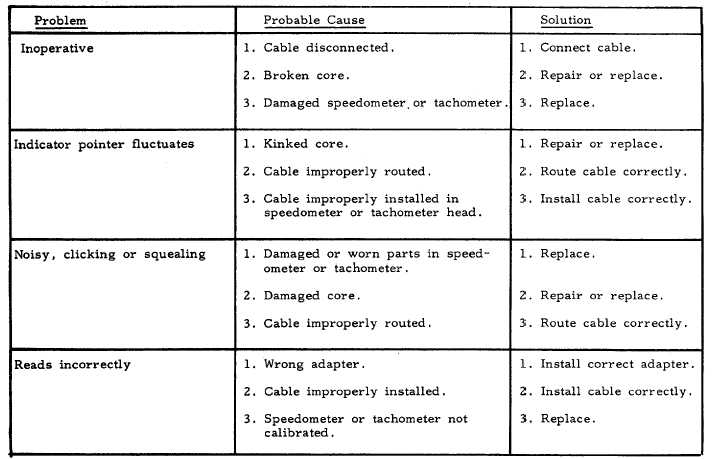

SPEEDOMETER, TACHOMETER AND CABLE TROUBLE SHOOTING

Remove

1.

Disconnect upper end of speedometer or tachometer

cable by removing four mounting screws from

instrument cluster and detaching cluster enough to

expose back of cluster.

2.

Depress spring clasp on back of speedometer or

tachometer and release cable (Fig. 4).

3.

Unscrew cable lower or drive end from adapter at

either transmission or engine component.

4.

Unfasten cable from any ties or clips and remove

complete cable assembly from chassis.

Inspect

1.

Pull the flexible core out of case and check for kinks by

rolling core on a flat surface.

2.

A core kink will show up as a hop at kinked point.

3.

Check for frayed spots by running core loosely through

fingers.

Repair or Replace Core

Never reuse a kinked or frayed core. A kinked core will

cause a fluctuation of speedometer or tachometer reading and a

frayed core will fail completely a short time after being returned

to service.

IMPORTANT

If replacement core is used, be sure core is not

too long. A long core will cause a damaging

thrust to head of speedometer or tachometer

when installed.

Install

Apply a thin coat of lubricant (IH #251H EP) to core at

reassembly as follows:

1.

Place approximately 1 teaspoon of lube in one hand.

CTS-2735 Page 8

PRINTED IN UNITED STATES OF AMERICA

|