|

| |

TRUCK SERVICE MANUAL

TM 5-4210-230-14&P-1

FUEL SYSTEM

7.

Take out the two valve housing-to air dome and filter

cover mounting screws and separate the valve housing

from the air dome and filter cover. Remove the air

dome diaphragm.

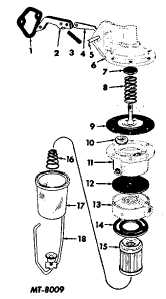

Fig. 5 Exploded View of Suspended Bowl Type Fuel Pump

Legend for Fig. 5.

Key

Description

1

GASKET, Mounting

2

LEVER, Cam

3

SPRING, Cam Lever

4

LEVER, Diaphragm

5

PIN, Cam Lever

6

BODY, Pump

7

SEAL, Oil Assembly

8

SPRING, Diaphragm

9

DIAPHRAGM, Pump

10

VALVE, Inlet and Outlet

11

HOUSING, Valve

12

DIAPHRAGM, Air Dome

13

COVER

14

GASKET, Element Bowl

15

ELEMENT, Paper or Ceramic

16

SPRING, Element (If Used)

17

BOWL, Fuel

18

RETAINER, with SCREW

Inspection

Whenever the fuel pump is serviced there are some

parts which should always be replaced whether the old parts

appear serviceable or not. These parts are the diaphragm

assembly, air dome diaphragm, filter bowl gasket, ceramic or

paper filters, valve and cage, cam lever shaft seal plug and

the pump-to-crankcase gasket. Fuel pump repair kits

containing all these parts are available. All other parts should

be inspected as follows:

1.

Inspect the pump body, valve housing, air dome and

filter cover for cracks or breakage in castings.

2.

Check the mating surfaces of castings for warpage.

3.

Inspect the body and cover for stripped screw threads.

4.

Check the rocker arm for wear at the camshaft contact

point and also at the pivot point.

Assembly

All suspended or side-mounted bowl type fuel pumps

will have an assembly procedure similar to the following.

Refer to Fig. 6.

1.

Place new air dome diaphragm (9) on the dome section

of air dome and filter cover (10). Position the open half

of the diaphragm over the inlet section of the air dome.

2.

Install the valve and cage assembly in the valve

housing if they were removed.

3.

Assemble valve housing assembly (7) to the air dome

and filter cover assembly so that the intake side of the

housing mates with the intake side of the air dome.

Insert two mounting screws (6) with lockwashers and

tighten securely.

4.

Install new diaphragm assembly (5) to pump body (20).

5.

Insert cam lever (1) into the opening in the pump body.

Compress the diaphragm spring slightly so that the

forked end of the cam lever engages under the retainer

on the end of the diaphragm spring.

6.

Fasten the cam lever in the pump body with cam lever

pin (21) and secure the pin with cam lever shaft

retaining spring pin (4). Seal the pin opening in the

pump body with cam lever shaft seal plug (3).

7.

Check the match marks made at the time of

disassembly on the pump body and valve housing

assembly and install the valve housing assembly to the

pump body.

8.

Install mounting screws (8) with lockwashers but

tighten only enough for the screws to just touch the

lockwashers.

CTS-2050-F Page 7

PRINTED IN UNITED STATES OF AMERICA

|