|

| |

ENGINE DIVISION SERVICE MANUAL

TM 5-4210-230-14&P-1

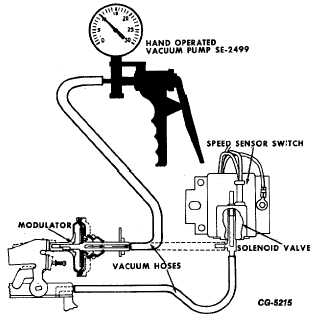

Fig. 61 Modulator Test

(5)

If modulator is improperly adjusted, loosen lock nut

and adjust position of modulator.

(6)

Repeat Steps (3) thru (5) until proper speed is

achieved; then tighten lock nut.

(7)

Reconnect proper vacuum hose to modulator.

c.

Perform DTM operational test as follows:

(1)

Verify modulator is retracted at idle.

(2)

Slowly accelerate the engine and observe the speed

at which the modulator extends. Modulator should

extend at 1850 + 50 RPM (Fig. 60).

(3)

Slowly decelerate the engine and observe the speed

at which the modulator retracts. Modulator should

retract at 1850 + 50 RPM (Fig. 60).

d.

Verify solenoid valve functions properly.

(1)

Operate engine at any condition.

(2)

With wiring harness disconnected from solenoid

valve, modulator must be in retracted position.

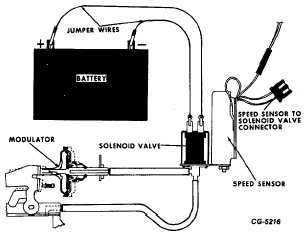

Fig. 62 Jumper Wires from Battery to Solenoid Valve

Terminals

(3)

With jumper wires from positive terminal of battery

and from ground connected to solenoid valve

terminals (Fig. 62), modulator must be in extended

position.

(4)

If modulator does not function properly, solenoid

valve is faulty and must be replaced. (The solenoid

valve and speed sensor are sold as one assembly.)

e.

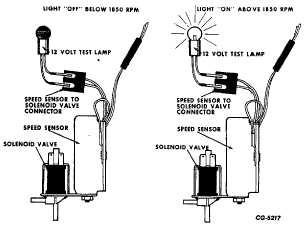

Verify speed sensor functions properly.

(1)

Disconnect wiring harness from solenoid valve and

connect a 12-volt test lamp between the two

terminals of the harness connector.

Fig. 63 Speed Sensor Switch Test

CGES-215 Page 36

PRINTED IN UNITED STATES OF AMERICA

|