|

| |

ENGINE DIVISION SERVICE MANUAL

TM 5-4210-230-14&P-1

NON-SCHEDULED MAINTENANCE OPERATIONS

DECELERATION THROTTLE MODULATOR (DTM)

SYSTEM

Deceleration Throttle Modulator

System Operation

The deceleration throttle modulator system consists

basically of a vacuum operated throttle modulator unit on the

carburetor, a solenoid vacuum valve and engine speed sensor

unit.

Normally an engine will emit relatively high levels of

unburned hydro-carbons during "closed throttle" deceleration.

This is because the intake of fuel/air mixture is not sufficient

to support complete combustion and the engine "misfires"

resulting in fuel being passed through the engine unburned.

The deceleration throttle modulator system overcomes this

condition by maintaining a slightly greater throttle opening

(high idle) during initial deceleration which permits intake of

just enough additional fuel/air mixture to promote combustion

and eliminate misfire.

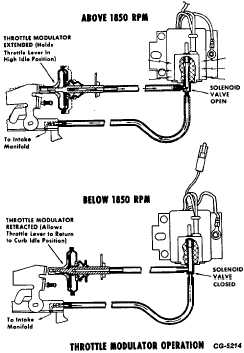

The engine speed sensor is calibrated to activate or

deactivate (extend or retract) the throttle modulator unit at

approximately 1850 RPM engine speed. Operation of the

throttle modulator is illustrated in Fig. 60.

Above 1850 RPM engine speed, the solenoid vacuum

valve is activated (held open) by electrical current from the

engine speed sensor unit. This permits manifold vacuum to

act upon the diaphragm of the throttle modulator unit

extending the modulator unit to the high idle position. Upon

deceleration, the returning carburetor throttle level contacts

the extended modulator, thus holding the throttle in high idle

position.

When engine speed drops below 1850 RPM, the speed

sensor unit deactivates the solenoid vacuum valve allowing

the valve to close and bleed the vacuum from the throttle

modulator diaphragm chamber. This permits the diaphragm

spring to retract the modulator unit and allow the throttle lever

to return to normal curb idle position.

Check Deceleration Throttle Modulator

Operation, replace if necessary.

a.

Check modulator for free operation by grasping

modulator by large diameter of the plastic

housing and pulling (without twisting) toward throttle

lever. Plastic housing should move freely against

internal spring force for about 6 mm (¼ "). Modulator

should be replaced if it does not move freely or does

not return rapidly to fully retracted position (Fig. 60).

b.

Check throttle modulator speed setting and adjust, if

necessary.

(1)

Connect tachometer to engine.

(2)

Start and operate engine until normal operating

temperatures are reached.

Fig. 60 Throttle Modulator Operation

(3)

Disconnect vacuum hose from modulator and

manually apply vacuum to modulator (Fig. 61). If

modulator does not extend, unit is faulty and must be

replaced. Allow throttle to close against extended

modulator.

(4)

Observe engine speed. For proper speed, see

Emission Control Tune-Up Specifications.

CGES-215 Page 35

PRINTED IN UNITED STATES OF AMERICA

|