|

| |

ENGINE DIVISION SERVICE MANUAL

TM 5-4210-230-14&P-1

b.

Be sure hoses are connected properly to low

temperature vacuum control valve.

c.

If hoses are satisfactory and vacuum does not pass

through low temperature vacuum control valve, valve

is faulty and must be replaced.

After correcting any problem and obtaining a vacuum

signal at EGR valve, repeat System Operation Test per c and

d above.

Check operation of EGR valve as follows:

a.

Remove EGR valve from engine.

b.

Visually inspect valve for evidence of valve pintle

(plunger) not seating. If pintle does not seat due to

deposits, clean valve pintle and seat (see EGR Valve

Cleaning Procedure). If pintle does not seat properly

after cleaning, replace EGR valve.

c.

Apply 10-12" Hg vacuum to EGR valve vacuum port

(Fig. 51). As vacuum is applied, valve pintle should

move off seat and retract into valve housing until end

of pintle is approximately flush with surface of valve

housing. If valve does not operate when vacuum is

applied, valve is faulty and should be replaced. 15A.

Replace EGR Valve

15A.

Replace EGR Valve

Because EGR valve metering varies between engines, it

is important that the correct EGR valve be used in order to

obtain optimum engine performance and emission control

(see EGR Valve Application Chart).

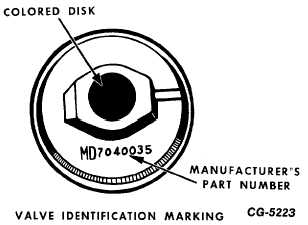

To assist in identification, EGR valves are coded by a

colored disk attached to the center of the vacuum diaphragm

housing. The valve may also be identified by the

manufacturer's part number stamped on the valve (Fig. 54).

15B.

Exhaust Gas Recirculation System Operation.

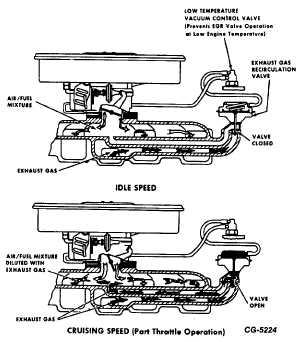

The exhaust gas recirculation (EGR) system introduces a

metered amount of exhaust gas into the intake manifold

where it mixes with the air/fuel mixture entering the

combustion chambers. Dilution of the air/fuel mixture with

exhaust gas lowers combustion temperature and pressure,

thereby reducing formation of oxides of nitrogen.

Fig. 54 EGR Valve Identification Marking

Fig. 55 Exhaust Gas Recirculation System

(Single Diaphragm EGR Valve)

The EGR valve regulates the amount of exhaust gas

entering the intake manifold. The EGR valve is controlled by

ported vacuum, which is determined by position of the

carburetor throttle plate(s). Operation of the exhaust gas

circulation system is illustrated in Figures 55 and 56.

While the engine is stopped or operating at idle speed

(negligible port vacuum), the EGR valve is held closed by

spring pressure.

CGES-215 Page 30

PRINTED IN UNITED STATES OF AMERICA

|