|

| |

ENGINE DIVISION SERVICE MANUAL

TM 5-4210-230-14&P-1

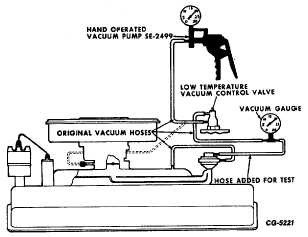

If minimum speed drop specification is not achieved,

verify applied vacuum signal acts on valve.

a.

Tee vacuum gauge into vacuum hose at EGR valve

(upper port on dual diaphragm valves).

b.

With

engine

shut

off

and

normal

operating

temperature (EGR low temperature vacuum control

valve), any vacuum magnitude applied at carburetor

end of vacuum hose should be observed at EGR

valve end of hose (Fig. 52).

c.

If same vacuum is not observed, inspect vacuum

hoses for leaks and replace as necessary.

d.

Repeat Step b. If same vacuum is not observed,

replace EGR low temperature vacuum control valve.

e.

Repeat EGR System Functional Test.

If minimum speed drop specification is still not achieved,

check for plugged exhaust gas passages and clean as

required.

Fig. 52 Low Temperature Vacuum Control Valve and

Connecting Hose Test

a.

Open carburetor throttle plates and examine exhaust

gas ports located in floor of intake manifold directly

below carburetor. If ports are plugged with deposits

remove carburetor and clean ports as needed.

For Canada V-304/345 Engines Only

a.

Operate engine until it reaches normal operating

temperature.

b.

Shut off engine. Connect tachometer and vacuum

gauge to engine.

c.

Start engine and block throttle open to give 3000

RPM. Observe and record tachometer reading.

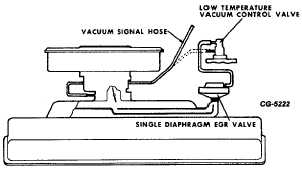

Fig. 53 Single Diaphragm EGR Valve System

d.

Disconnect EGR vacuum signal hose (Fig. 53) and

again record tachometer reading. If EGR system is

functioning properly the minimum speed increase

should be 50 rpm for the V-304 and 150 rpm for the

V-345. If rpm increase is less than shown above,

EGR system is not functioning properly and should

be checked per the following steps.

Check low temperature vacuum control valve as follows:

a.

With engine operating at fast idle, disconnect

vacuum signal hose from low temperature vacuum

control valve. A vacuum signal should be felt at the

open end of hose. If vacuum is felt, reconnect hose

and proceed. If vacuum is not felt, stop engine and

check for leaking or restricted vacuum hose or

restricted vacuum port in carburetor.

b.

With engine operating at fast idle, disconnect

vacuum signal hose from EGR valve. A vacuum

signal should be felt at the open end of the hose. If

vacuum is felt, vacuum supply and low temperature

valve are satisfactory (Fig. 53).

If vacuum is not felt:

a.

Check for leaking or restricted vacuum hose.

CGES-215 Page 29

PRINTED IN UNITED STATES OF AMERICA

|