|

| |

ENGINE DIVISION SERVICE MANUAL

TM 5-4210-230-14&P-1

idle, cruise, acceleration, etc.). The valve itself consists of a

coil spring, valve and a two-piece outer body which is crimped

together. The valve dimensions, spring and internal

dimensions are such to produce the desired air flow

requirements.

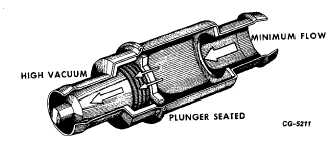

During the periods of deceleration and idle, manifold

vacuum is high. The high vacuum overcomes the force of the

valve spring and the valve bottoms in the manifold end of the

valve housing. This does not completely stop the flow but it

does restrict (Fig. 46).

Fig. 46 Plunger Position During Idle or Low Engine Speed

When the engine is accelerated or operated at constant

speed, intake manifold vacuum is less than at idle or during

deceleration. The spring force is stronger than vacuum pull

during this mode so the valve is forced toward the crankcase

end of the valve housing. With the valve in this position, more

crankcase vapors flow into the intake manifold (Fig. 47).

Fig. 47 Plunger Position During High Engine Speed

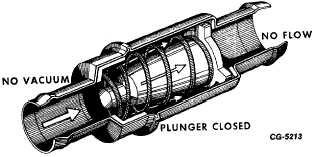

In the event of a backfire, the valve plunger is forced back

and seated against the inlet of the valve body.

This prevents the backfire from traveling through the

valve and connecting hose into the crankcase (Fig. 48). If the

backfire was allowed to enter the crankcase, it could ignite the

volatile crankcase blow-by gases.

Fig. 48 Plunger Position During Backfire or When Engine is

“OFF”.

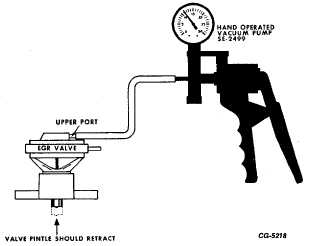

14. Remove and Check EGR Valve and Clean or Replace,

if necessary. (V-345 and V-392 Engines Only)

a.

Remove EGR valve from engine.

Fig. 49 EGR Valve Test

b.

Apply 10-12" vacuum to EGR valve vacuum port

(upper port of dual diaphragm valve). As vacuum is

applied, valve pintle should move off seat and retract

into valve housing (Fig. 49). If valve does not

operate when vacuum is applied, valve is faulty and

should be replaced.

c.

Visually inspect valve for evidence of valve pintle

(plunger) not seating or deposit accumulation on

pintle and seat. Clean

CGES-215 Page 27

PRINTED IN UNITED STATES OF AMERICA

|