|

| |

ENGINE DIVISION SERVICE MANUAL

TM 5-4210-230-14&P-1

engine to idle and observe position of inlet tube

damper. If damper has not rotated all or part way

down to allow some cold air to enter inlet tube,

replace temperature sensor.

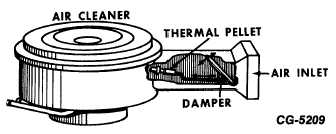

Procedure for servicing the thermal pellet type air cleaner

is as follows: (Cargostar & S-Series Vehicles)

a.

With the engine cold and ambient under hood

temperature below 32 deg. C (90 deg. F), the

damper should be closed to the cold air inlet (open to

the hot air inlet). This closed to cold air inlet can be

checked by looking in the end of the inlet.

b.

With the engine at operating temperature and the

ambient under hood temperature above 57 deg. C

(135 deg. F), thermal pellet should open the damper

allowing cold air to enter the cleaner and at the same

time shut off the hot air inlet.

Fig. 44 Pellet Type Controlled Air Cleaner

c.

If the damper does not operate as described above,

reach in the inlet, move the damper open and check

to see if it is sticking. If damper is moving freely and

the linkage is connected, then the thermal pellet must

be at fault and should be replaced.

When replacing the thermal pellet do not tighten the

pellet assembly with a tool. Tighten finger tight only.

Use locking compound on the threads to secure in

place. If a tool is used, too much pressure may be

applied changing the calibration of the thermal pellet

and linkage assembly.

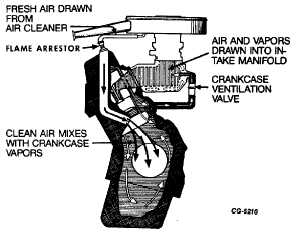

13. Check PCV System Hoses and Replace, if necessary,

Clean PCV Valve, If necessary.

a.

Remove valve from crankcase side, leaving the other

end of the valve in hose and connected to intake manifold.

b.

With the engine operating, a vacuum should be felt

at the end of the valve. If no vacuum is present, the

valve, hose and fitting should be removed and cause

of restriction determined.

c.

Check the inner chamber of the valve to see that it

can be moved freely. This may be accomplished by

inserting a stiff wire into the valve body and

observing whether or not the plunger can be readily

moved, or shake the valve and listen for rattle. If the

plunger does not move, soak in carburetor cleaner.

Fig. 45 Typical Air and Vapor Flow Through the System

13A.

Positive

Crankcase

Ventilation

Valve

(PCV)

Operation.

Since the vacuum supply for the PCV system is from the

intake manifold, the flow through this system into the manifold

must be controlled in such a manner that it varies in

proportion to the air-fuel ratio being drawn into the intake

manifold.

The PCV valve varies the amount of flow through the

system according to the various modes of operation (i.e.

CGES-215 Page 26

PRINTED IN UNITED STATES OF AMERICA

|