|

| |

ENGINE DIVISION SERVICE MANUAL

TM 5-4210-230-14&P-1

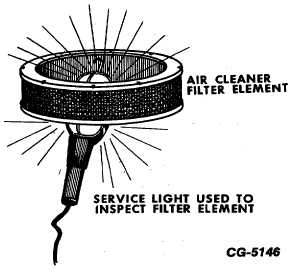

to outside. Check element for punctures or splits by

looking through filter paper toward light held in center

of element. Do not wash element. Replace with new

element, if necessary.

Fig. 7 Dry Type Air Cleaner Filter

b.

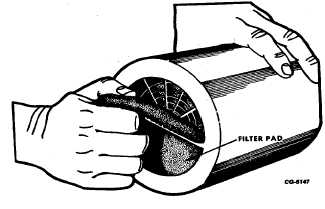

Foam Wrap Dry Type Remove air cleaner element

assembly, clean any accumulation of dirt from air

cleaner housing. Remove foam wrap from element,

and tap element lightly on a flat surface or use low

air pressure to remove dirt particles. Blow air from

inside filter element to outside. Check element for

punctures or splits by looking through filter paper

toward light held in center of element. Do not wash

element. Replace with new element, if necessary.

Wash foam wrap in soap and water and dry with

compressed air. Submerge foam wrap in light

engine oil and squeeze excess oil from wrap.

Replace damaged wrap, if necessary. Install foam

wrap on element and reassemble air cleaner.

c.

Oil Bath Type - Remove air cleaner from engine.

Remove oil sump and drain oil. Wash sump and

mesh filter element in solvent and dry with

compressed air. Refill sump and oil mesh element

with engine oil of same viscosity used in the engine.

Allow excess oil to drip from element before

reassembly. Reinstall air cleaner.

7. Replace Filter at Bottom of Evaporative Vapor Storage

Canister (where used).

The air filter located at the bottom of the vapor

storage canister (Fig. 8) should be replaced at the interval

shown on the Maintenance Intervals Chart, or more frequently

under severe dusty conditions.

Fig. 8 Vapor Storage Canister Air Filter Location

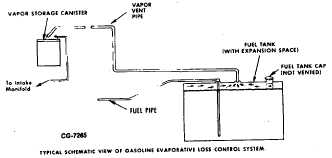

7A. Gasoline Evaporative Loss Control System

In compliance with California air pollution control

regulations, all IH gasoline powered vehicles sold in California

will utilize gasoline evaporative loss control system which

reduces the amount of gasoline vapors entering the

atmosphere from the vehicle's fuel system. Below is a

schematic view of a typical gasoline evaporative loss control

system.

Fig. 9 Typical Schematic View of Fuel Tank Gasoline

Evaporative Loss Control System

To accomplish evaporative control the system must

perform three basic functions:

CGES-215 Page 9

PRINTED IN UNITED STATES OF AMERICA

|