|

| |

ENGINE DIVISION SERVICE MANUAL

TM 5-4210-230-14&P-1

d.

Reinstall cap onto distributor.

e.

Inspect high tension ignition cables for cracks or

deterioration and replace defective cables.

4. Replace all Spark Plugs, Check Required Voltage and

Replace any Defective Plugs.

a.

Remove used spark plugs.

b.

Check gap of new spark plugs (see Emission Control

System Tune-Up Specifications) and adjust gap, if

necessary.

Continuous light load operation may produce spark

plug fouling, necessitating more frequent spark plug changes

than are indicated in the Maintenance Intervals. A change in

plug heat range will not correct fouling under these conditions.

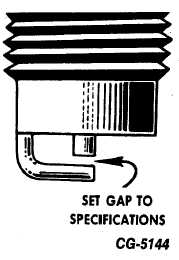

To change spark plug gap, bend the outer electrode;

never bend the center electrode. Be accurate use a round

wire gauge to check the electrode gap. Check the gap of new

spark plugs before installation and tighten to specified torque.

Fig. 5

IH Branches and Dealers are equipped with spark

plug

cleaning

and

testing

equipment

which

renders

dependable service.

c.

Install new spark plugs and torque to specifications

(see

Emission

Control

System

Tune-Up

Specifications.

d.

Install high tension spark plug cables onto spark plug

terminal.

IMPORTANT

When replacing high tension spark plug cables, be sure

cables are routed to proper spark plugs (refer to firing

order cast into intake manifold).

e.

Connect Tune-Up Scope Tester No. SE-2440, or

equivalent.

f.

Start and operate engine until normal operating

temperatures are reached. Then operate engine at

1000 RPM.

g.

Observe required voltage (see Emission Control

System Tune-Up Specifications).

h.

If required voltage is out of specifications on any

cylinder, replace spark plug and repeat Steps a

through g.

5. Replace Fuel Filter.

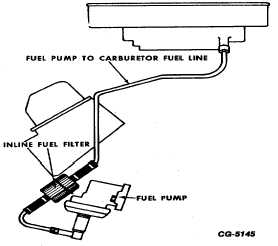

Inline fuel filters are used on most IH engines (Fig.

6). This type of filter is inexpensive and easy to replace when

needed.

Fig. 6 Inline Fuel Filter Typical on Most Gasoline Engines

6. Clean or Replace Air Cleaner Filter.

a.

Dry Type - Remove air cleaner element, clean any

accumulation of dirt from air cleaner housing. Tap

element lightly on a flat surface or use low air

pressure to remove dirt particles. Blow air from

inside filter element

CGES-215 Page 8

PRINTED IN UNITED STATES OF AMERICA

|