|

| |

ENGINE DIVISION SERVICE MANUAL

TM 5-4210-230-14&P-1

TROUBLE SHOOTING

ELECTRONIC VACUUM MODULATING (EVM) GOVERNOR

SYSTEM TROUBLE SHOOTING PROCEDURE

The following procedure presents a J systematic

method of diagnosing and trouble shooting the Electronic

Vacuum Modulating (EVM) Governor System. Each trouble

shooting step has a chart to locate the component and

illustrate the test. Test instruments used consist of a volt-

meter and a tachometer.

It is recommended that the tachometer used for

testing governor no load speed be an instrument with a high

percentage of accuracy. The governed no load speed should

be within a 100 RPM tolerance.

If engine speed reading is more than 100 RPM high

or lower than the specified governed no load speed, make

sure the tachometer being used has been properly calibrated

before condemning the ECU or vacuum solenoid valve.

Figure 61 Anti Tamper Proof Seal

Electrical connections on the EVM system are sealed

with an anti-tamper proof seal tape which is placed on the

connectors at the time of assembly. The production seal tape

can be identified by its white color with black print. If the

connector seal tape is tampered with the word VOID will

appear.

After service is performed, a service anti-tamper

proof tape which is white in color with red print should be

installed. This difference in print color will show the system

has been serviced.

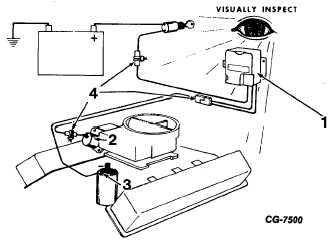

1. Visually inspect condition of wiring connections and

components.

2. Disconnect wire at electronic control unit (ECU).

Check for battery voltage with ignition turned on. If

battery voltage is not found, refer to Service Manual,

ELECTRICAL, for repair. If battery voltage is found,

proceed to Step 3.

Figure 62. Step 1

1. Electronic Control Unit (ECU)

2. Solenoid Vacuum Valve

3. Ignition Coil

4. Cable Connections Figure

Figure 63. Step 2

1. Ignition Switch “ON”

2. Battery Voltage

3. Volt Meter

4. Battery Source to ECU Cable

3.

Disconnect ECU signal cable at terminal

connector as shown.

a. Check continuity of cable from negative side

of coil to ECU end. If reading indicates an

open circuit, replace cable.

CGES-125-T Page 41

ENGINE DIVISION SERVICE MANUAL

TM 5-4210-230-14&P-1

|