|

| |

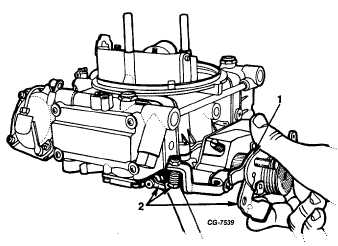

Figure 55. Accelerating Pump Lever Adjustment

1. Location of Pump Cam

2. Clearance Between Pump Lever and Adjusting Screw With

Throttle Wide Open

Accelerating Pump Stroke Adjustments

To satisfy acceleration requirements in various climates, the

accelerating pump discharge can be adjusted (Fig. 55).

The bottom hole (No. 2) in the acceleration pump cam and

the throttle lever provides the maximum pump discharge for

extreme cold weather and the top hole (No. 1) provides the

minimum pump discharge for warm weather operation. If a

change in the adjustment is required, make certain the proper

hole (top or bottom) in plastic accelerating pump cam, located

behind the throttle lever, is properly aligned (indexed) with the

numbered hole (top or bottom) in the throttle lever before

installing the retaining screw.

Dashpot

With engine temperature normalized and engine operating at

specified curb idle speed, depress dashpot plunger and

measure distance between plunger and throttle lever (see

SPECIFICATIONS). The shank of a new drill may be used to

check this adjustment.

To adjust the setting, loosen locknut and screw the dashpot in

or out as required. When the desired setting is obtained,

tighten locknut on dashpot against the bracket. Recheck idle

speed.

Throttle Modulator

With vacuum applied to throttle modulator loosen locknut and

adjust modulator until engine operates at specified RPM (see

SPECIFICATIONS).

Governor Adjustment (Spinner Type)

The procedure outlined below should be followed

when making a governor spinner adjustment. It is necessary

to use a tachometer to adjust engine RPM.

Adjust the governor spinner so that engine speed will

cut off within the engine no load cutoff range (see

SPECIFICATIONS).

1.

Turn off ignition. Engine must be completely

stopped.

2.

Remove governor clamp and gasket assembly.

3.

Turn engine over until adjusting screw whole

plug appears in the opening.

4.

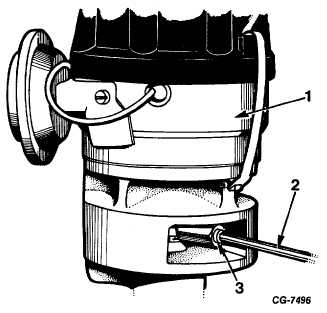

Remove plug with 1/8” Allen Wrench (Fig. 56).

Figure 56 Using Allen Wrench to Remove

Governor Plug

Fig. 56. Using Allen Wrench to Remove Governor Plug

1. Distributor 2. Allen Wrench

3. Governor Plug

5.

Insert slotted end of SE-2072-2 governor

adjusting tool firmly in hole, engaging

adjusting tang (Fig. 57). Turn the handle

clockwise to decrease speed and counterclockwise

to increase speed; ¼ turn will

change

the

speed

approximately 100 RPM.

6.

The adjusting screw is of a special design. The

spinner cannot be adjusted with a screwdriver

or

by

any

device other than this

tool.

7.

Reinstall plug with 1/8” Allen Wrench before

checking governor speed.

CGES-125-T Page 38

PRINTED IN UNITED STATES OF AMERICA

ENGINE DIVISION SERVICE MANUAL

TM 5-4210-230-14&P-1

ADJUSTMEN PROCEDURE

|