|

| |

TRUCK SERVICE MANUAL

TM 5-4210-230-14&P-1

FRAMES

Welding

Position

Amperes

Voltage

Downhand

130/140

21/23

Overhead

130/140

21/23

Vertical Up

110/120

22/24

Use low hydrogen electrodes which have superior crack

resistance and notch toughness similar to AWS-E11018. This

type electrode should be stored in a moisture-free container to

avoid porosity during welding.

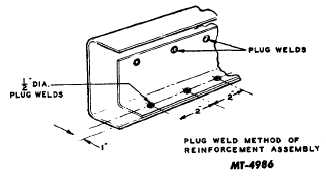

Fig. 9

Full Length Reinforcement

When heat treated frames are to be reinforced over a

greater portion of their length, frame channel reinforcements

should be installed using bolts. Bolts of high strength material

conforming to SAE grade 5 or better should be used. The

bolts and nuts should be inspected periodically and kept tight,

since the strength of the reinforcement depends somewhat on

the maximum clamping force between the members.

Drilling

The drilling of heat treated frame rails presents no

unusual difficulty. Standard high speed drills of good quality

will serve provided they are sharpened properly and not

overheated during sharpening or use. There are, however,

special high speed twist drills available having special

materials which will hold a cutting edge longer. These drills

are expensive and require especially rigid support, otherwise

drill breakage will result. When drilling heat treated rails, like

in any other drilling operation, sufficient pressure must be

applied to the drill bit to maintain continuous cutting. The drill

point should frequently be drenched with cutting oil (soluble

oil) to help cool the drill. Avoid letting a drill bit turn in the

work without cutting. To do so will usually overheat and ruin

the drill.

The drill must be held steady during the drilling operation.

Avoid wobble or change of drill angle during the drilling

operation.

Frame Straightening

When heat treated frame rails have been bent or twisted,

they should not be heated for straightening. This work should

be done with the frame rails cold. Heating for straightening

purposes is likely to destroy the rail temper in localized areas,

which will bring about rail failures.

FIFTH WHEEL MOUNTING

The following information has been prepared to avoid any

unnecessary drilling of standard non-heat treated and heat

treated frame rails, especially at the frame rail flange when

the fifth wheel is being installed.

In no instance should welding be used to attach the fifth

wheel or mounting parts to the frame rails. The application of

the weld is likely to reduce the strength of the rail in the area

of the weld. Bolts must be used throughout the fifth wheel

installation. The only exception to welding in the fifth wheel

installation is the locating block installation at each corner as

shown in Figs. 10 and 11.

Figs. 10 and 11 show two methods of mounting the fifth

wheel. Fig. 10 shows mounting where the deck plate is

attached at frame rail level. This mounting can be modified to

raise the fifth wheel; however, the mounting should be

changed to that shown in Fig. 11. The mountings illustrated

in Figs. 10 and 11 should not be utilized without the use of a

deck plate.

Low Mounting

With reference to this type mounting Fig. 10 shows the

various details to follow. Note that the drawing shows a 4 x 3-

1/2" mounting angle at the frame rail which is cut out at the

spring hanger to provide 1/8" clearance.

Where rivets are present the mounting angles must be

drilled to provide clearance for rivet heads (C on drawing).

This applies to rivets in the frame flange as well as frame

side.

Bolts must be used throughout the installation of the fifth

wheel mounting. However, locating blocks can be welded to

the mounting angles as shown in Fig. 10. These blocks must

be welded in place before the angles are installed on the

frame rail.

CTS-2037-HA Page 7

PRINTED IN UNITED STATES OF AMERICA

|