|

| |

TRUCK SERVICE MANUAL

TM 5-4210-230-14&P-1

FRAMES

b.

Preheat the frame rail along the crack area to

500-600 degrees to burn off excess oil or paint

then permit heated area to cool to 200

degrees or below before welding is started.

Under no circumstances should the rail be

heated to a temperature exceeding 900-950

degrees F. since this is the tempering

temperature of the rail.

c.

Either alternating current or direct current

reversed polarity, combined with a short arc

and a beading or narrow weave technique

may be used. Direct current reversed polarity

is recommended or preferred.

d.

Slag should be removed after each pass and

an interpass or constant temperature of 200

degrees should be maintained.

e.

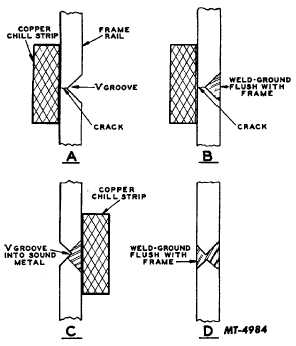

When sufficient metal has been deposited, the

weld bead should be ground flush, Fig. 7, with

the surface being repaired.

Fig. 7.

f.

Where both sides of the frame rail are

accessible, a V-groove is ground from the side

opposite the repair and the procedure outlined

above

repeated.

Dependent

upon

accessibility, "chill" strips should be used

wherever possible. The V-groove ground on

the opposite side

of the repair should be deep enough to enter the sound metal

of the first weld repair "C" of Fig. 7.

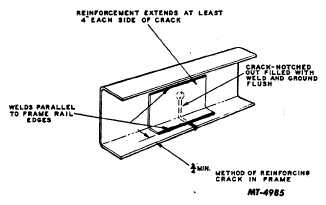

Frame

Welds on heat treated material tend to reduce physical

properties in the weld heat-affected zone. Because of this, it

is recommended that all reinforcements be designed so that

all welds are parallel, rather than perpendicular to the frame

rail edges. Welds perpendicular to the flange edges will

reduce the carrying capacity of the rail, Fig. 8 and 9.

Fig. 8

The edge of the reinforcement flange to the edge of side

rail flange dimension should be held to a minimum of three

quarters of an inch to keep the heat-affected zone from

extending to the sidemember flange edge. Wherever

possible, it is recommended that plug welds of the type shown

in Fig. 9, be substituted for edge welds when assembling the

reinforcement to the side rail. Plug welds offer the

advantages of a reduced heat-affected zone plus increased

flexibility and reduced stress concentrations. When using this

method, one half inch (minimum) diameter holes should be

drilled and chamfered in the reinforcement on 2" center to

center distances. At no time should these holes be drilled in

the frame rail being repaired. The reinforcement should then

be installed in its proper position on the sidemember and the

holes filled with weld material.

Again

a

minimum

dimension

of

3/4"

should

be

maintained between the weld and the edge of the sidemember

flange. The voltage, amperage and pre-heat specifications

listed below should be followed.

CTS-2037-A Page 6

PRINTED IN UNITED STATES OF AMERICA

|