|

| |

ENGINE DIVISION SERVICE MANUAL

TM 5-4210-230-14&P-1

ENGINE

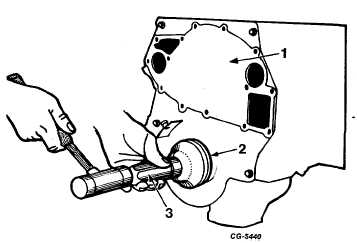

NOTE: With the engine front cover assembled to the

cylinder block, a new oil seal can also be installed using

SE-1949 installer as shown in Figure 148. Install oil seal

flush to .010" below front face of front cover.

Fig. 148 Installing Engine Front Cover Oil Seal with Cover

Assembled to Cylinder Block Using SE-1949

Installer

1. Front cover

2. Oil seal

16. Position a new front cover gasket to the cylinder block

and install the engine front cover assembly. Dowel pins

are provided for proper alignment.

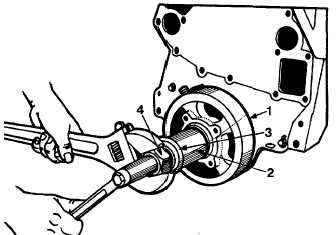

17. Install woodruff key in the crankshaft and install the

crankshaft vibration damper using SE-1900 installer and

SE-1900-18 adapter, Figure 149, with thrust bearing to

reduce friction. Install damper bolt and washer and

tighten to specified torque. See "Torque Chart."

18. Install crankshaft pulley on vibration damper with bolts

and lockwashers. Tighten to specified torque. See

"Torque Chart."

19. Install oil pump, pick-up tube and screen assembly.

Check alignment of pump to cylinder block for free

movement of oil pump shaft. There should be no bind if

the pump is correctly aligned.

20. Place the flywheel in position on the crankshaft. Apply

sealing compound not affected by oil to the threads of the

flywheel mounting bolts. Avoid getting sealing compound

on mating

surfaces of flywheel and crankshaft. Install mounting

bolts to specified torque.

Fig. 149 Installing Crankshaft Vibration Damper

Using SE-1900 Installer and SE-1900-18

Adapter

1. Damper

3. Thrust bearing

2. Sleeve

4. Nut

21. Install the clutch pilot bearing into the flywheel. To

assure the clutch pilot bearing does not rotate in the

flywheel bore, it is recommended that Loctite grade B be

applied evenly around the O.D. of the bearing and the

I.D. of the flywheel bore at the time of installation. Do

not allow Loctite to contact inside of bearing or between

flywheel and crankshaft.

After the Loctite grade B has been applied, allow to cure

for 1 to 2 hours. The interval required to reassemble the

vehicle from the point of clutch bearing is considered

adequate for the curing of Loctite.

22. Place the clutch driven disc against the flywheel so the

long portion of the hub is toward the rear. Place the

clutch in position on the flywheel over the clutch driven

disc, install two or three mounting bolts and lockwashers

loosely. Install a clutch aligning arbor, if available, or a

transmission main drive gear shaft, Figure 150, through

the clutch driven disc hub spline and into the clutch pilot

bearing. Hold the clutch driven disc in position while

completing installation of the remaining mounting bolts

and lockwashers in the flange of the clutch backing plate

or cover. Tighten all bolts

CGES-210 Page 60

PRINTED IN UNITED STATES OF AMERICA

|