|

| |

ENGINE DIVISION SERVICE MANUAL

TM 5-4210-230-14&P-1

ENGINE

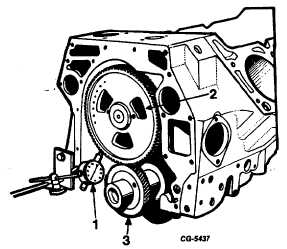

Fig. 145 Checking Camshaft and Crankshaft Gear

Backlash

1. Dial indicator

3. Crankshaft gear

2. Camshaft gear

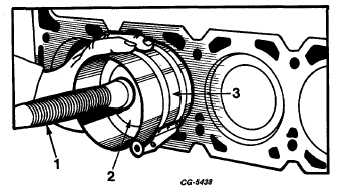

12. Turn the crankshaft so No. 1 crankpin is at the top of its

stroke. Coat the cylinder bores, crankshaft journals,

pistons, piston pins and piston rings with engine oil.

Insert the piston into the ring compressor and install the

piston assembly into its respective cylinder bore, Figure

146. Make certain the odd numbers stamped on the

connecting rods (1-3-5-7) are facing toward the right side

of the cylinder block, while even numbers (2-4-6-8) are

facing the left side of the cylinder block. Install the

connecting rod bearings and caps, coating each bearing

shell surface on both sides with engine oil. The

numbered side of the cap must match and be on the

numbered side of the rod.

NOTE: If the connecting rods and bearing caps are

properly installed, the large chamfer side of the rod

and cap will be to the fillet side of the crankpin.

Install new bearing cap bolts, washers and nuts and

tighten to the specified tortue as shown in "Torque

Chart."

13. Follow the procedure outlined in Step 12 for the

remaining connecting rods and pistons.

14. Recheck connecting rod end play using a feeler gauge as

outlined under "Fitting Connecting Rod Bearings" in

CLEANING, INSPECTION AND RECONDITIONING.

Fig. 146 Installation of Piston in Cylinder Block

1. Hammer handle

3. Ring Compressor

2. Piston

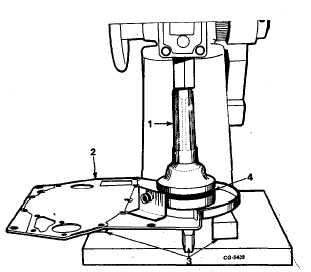

15. Press new oil seal in engine front cover using SE-1949

installer and support blocks, Figure 147. Install oil seal

flush to .010" below front face of front cover.

Fig. 147 Pressing New Seal in Engine Front Cover Using SE-

1949 Installer and Support Blocks

1. Installer

3. Support blocks

2. Front cover

4. Oil seal

CGES-210 Page 59

PRINTED IN UNITED STATES OF AMERICA

|