|

| |

ENGINE DIVISION SERVICE MANUAL

TM 5-4210-230-14&P-1

ENGINE

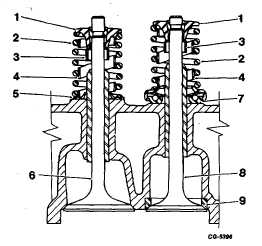

spring retainer. On the intake valves, install the valve spring

seat, valve stem seal, valve spring, damper and spring

retainer.

NOTE:

Care should be taken to see the valve stem

seals are installed correctly. If they are

not, their effectiveness in directing oil to

the valve guide could be reduced, Figure

117. Notice the valve stem seal is under

the spring retainer.

Fig. 117 Cross Section of Intake and Exhaust Valves Installed

in Head

1.

Retainer

6.

Intake valve

2.

Spring

7.

Roto coil

3.

Seal

8.

Exhaust valve

4.

Damper

9.

Insert

5.

Seat

Compress the valve springs with a valve spring

compressor and install the valve spring retainer locks. Be

sure the retainer and locks are correctly seated on all valves.

The cylinder head assembly complete with valves is

ready for installation on the cylinder block or crankcase.

Rocker Arm Assembly

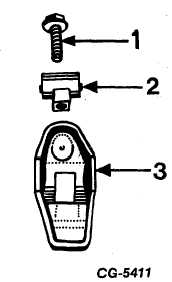

Individually mounted rocker arms are retained by

flange head retaining bolts and pivot balls, Figure 118. All

parts must be retained in the same order as they were on the

engine.

Clean all parts with a good cleaning solvent and use

compressed air to clean out the oil passages in the rocker

arms.

Fig. 118

1.

Retaining bolt

3.

Rocker arm

2.

Pivot ball

Inspect the pivot surface of each rocker arm and

pivot ball and replace any parts which are scuffed, pitted or

excessively worn. Inspect the valve stem contact surface of

each rocker arm and replace any rocker arm which is deeply

pitted. Inspect the rocker arm retaining bolts for excessive

wear or looseness in the cylinder head: replace if condition

exists.

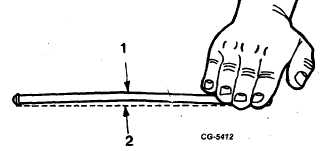

Push Rods

The push rods are hollow and serve as oil galleries to

lubricate each individual rocker arm assembly. Prior to

installation the push rods should be cleaned thoroughly and

inspected for wear and deposits which may restrict the flow of

oil to the rocker arm assemblies.

Check all valve lifter push rods for straightness by

rolling on a flat surface, Figure 119

Fig. 119 Checking Push Rod for Straightness

1.

Bent valve lifter rod

2.

Flat surface

CGES-210 Page 43

PRINTED IN UNITED STATES OF AMERICA

|