|

| |

ENGINE DIVISION SERVICE MANUAL

TM 5-4210-230-14&P-1

ENGINE

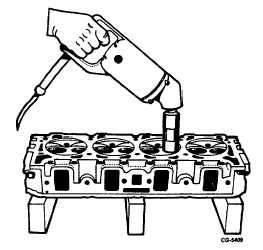

will be necessary to grind from the top and/or bottom of the

seat until the proper seat width is obtained using grinder

SE1631, Figure 115.

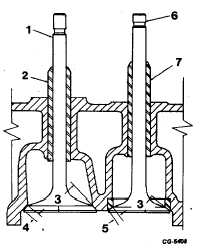

Fig. 114 Sectional View of Valves

1.

Intake valve

2.

Intake valve guide

3.

Angle

4.

A

5.

B

6.

Exhaust valve

7.

Exhaust valve guide

Fig. 115 Grinding Seats Using SE-1631 Grinder

Use a 60

angle grinding stone to remove stock from

the bottom of the seat (raise seat). Use a 30

angle stone to

remove stock from the top of the seat (lower seat).

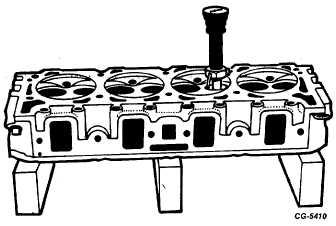

After

the

seat

grinding

operation

has

been

performed, it is necessary to check the seat for run-out, Figure

116. Seat run-out should not exceed limits as shown in

specifications.

Figure 116 Using Gauge from SE-1631 Tool Grinder Set for

Checking Seat Run-Out

It is important to have the finished seat face contact

the approximate center of the valve face. Position the valves

in the cylinder head. Place a thin coat of Prussian Blue on

each valve face and tap the valve lightly to its seat.

NOTE:

This is merely for test and proof of results

of refacing and reseating operations. A

poor grind job cannot be corrected by

lapping. Use of lapping compounds is not

recommended. A nearly perfect seat

often-times is destroyed by attempting to

lap the valves to their seats. Inspect each

valve for seat dimensions as outlined in

specifications and make any necessary

corrections.

The

corrections

should

always be made on the seat and not the

valve face.

NOTE:

New valves need not be refaced; however,

all valves should be carefully inspected for

damaged seat faces or for a run-out

condition due to a bent valve stem. Use

SE-2614 tool to determine the condition of

the valve.

If the ends of the valve stems are grooved or scored,

they may be ground to true up; however, remove only a

minimum amount of material. Rechamfer as necessary.

Wipe valve faces and valve seats with a cleaning

solvent to remove all dirt or foreign material. Coat the valve

stems and faces with oil and install the valves in the same

seats to which they were checked. On the exhaust valves,

install the Roto-Cap assembly, valve spring, valve stem

damper, valve stem seal and

CGES-210 Page 42

PRINTED IN UNITED STATES OF AMERICA

|