|

| |

ENGINE DIVISION SERVICE MANUAL

TM 5-4210-230-14&P-1

ENGINE

Inspect the valve springs for proper tension as

outlined in specifications. Any evidence of wear, cracks or

permanent sets will require replacement. SE-2241 spring

tester, Figure 104, or similar tool can be used to check

tension.

Inspect valve locks for excessive wear and replace in

pairs as required. Rotate the Roto-Coil assemblies and

replace if any wear or irregularities are noted. Note

particularly if the Roto-Coil is bound up or feels gritty.

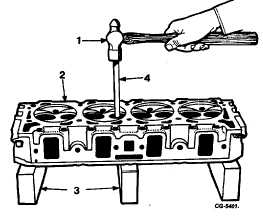

Remove SE-1939 Holding Fixture (if installed) and

position the cylinder head with combustion chamber facing

upward on support blocks, Figure 108. This preparation is

done for valve guide removal.

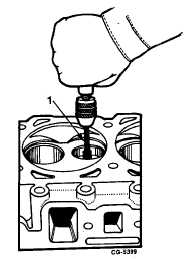

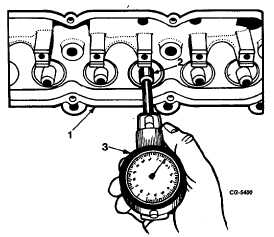

Check the valve guide bore dimensions (see

specifications). Prior to inspection it is necessary to clean

guides. There are many commercially available wire brushes

and scrapers, Figure 105, that clean guides very satisfactorily.

Similarly, there are various instruments for measuring the

guide bores small-bore gauge SE-2506, plug gauges, etc.,

Figure 106. Plug gauges of the "go" and "no-go" type are most

popular because of the facility with which guides can be

checked. However, there are two undesirable guide

conditions which are difficult to check with gauges of this type:

elliptical or egg-shaped bore wear and bell-mouthing at the

port of the guide. Careful guide inspection will detect egg-

shaped wear while careful use of the "no-go" gauge will tend

to show the degree of bell-mouthing. Replacement is

recommended for guides having bore diameters beyond the

recommended limit or which are bell-mouthed more than

.0005" or which show egg-shaped wear. Excessive guide

clearance prevents adequate cooling of the valve through the

guide and also allows deposits to tilt or tip the valve which

may cause valve breakage at high engine speed. These

conditions tend to prevent good seating and promote leakage

across the valve face. Excessive guide clearance also affects

the proper lubrication of the valve stem.

Fig. 105 Valve Guide Cleaning Tool

1. Cleaning tool

Fig. 106 Checking Guide Bore Using Gauge SE-2506

1.

Cylinder head

3.

Bore gauge

2.

Valve guide

Replacement guides are designed to give proper

clearance when installed in the cylinder head. Reaming is not

required but care must be taken to see that-the ends of the

guides are not burred during installation.

Fig. 107 Removing Valve Guides with SE-1722

1. Hammer

3. Support blocks

2. Cylinder head

4. Remover

CGES-210 Page 39

PRINTED IN UNITED STATES OF AMERICA

|