|

| |

TRUCK SERVICE MANUAL

TM 5-4210-230-14&P-1

ELECTRICAL

c.

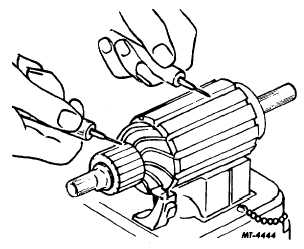

Grounds in the armature can be found using a

test lamp and prods, Fig. 9. If the lamp lights

when

one

prod

is

positioned

on

the

commutator and the other prod on the

armature core or shaft the armature is

grounded.

Fig. 9 Testing Armature for Grounds

If the commutator is worn, dirty, out-of-round or the

insulation is high, the commutator should be turned

down and under cut.

3.

Field Coils: Check field coils for grounds and opens

with a test lamp.

a.

Grounds:

With

the

field

coil

ground

disconnected, position one test prod on the

field frame and the other to the field

connector. If the lamp lights the field coils are

grounded and must either be replaced or

repaired.

b.

Opens: If the test lamp does not light when

the prods are connected to the ends of the coil

leads, field coils are open.

A pole shoe spreader and pole shoe screw driver

should be used if the field coils are to be removed. Extra

caution should be taken in replacing the field coils to prevent

grounding or shorting when they are tightened in place. If the

pole shoe has a long lip on one side, it should be assembled

in the direction of armature rotation.

REASSEMBLY

1.

Place the clutch assembly on the armature shaft.

2.

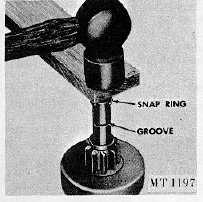

To aid in reinstalling the snap ring and retainer on

the armature shaft, proceed as follows.

a.

Place the retainer on the armature shaft with

the cupped surface facing the snap ring

groove.

b.

Place the snap ring on the end of the shaft.

With a piece of wood on top of ring, force the

ring over the shaft with a light hammer blow,

Fig. 10; then slide the ring down into the

groove.

Fig. 10 Installing Snap Ring

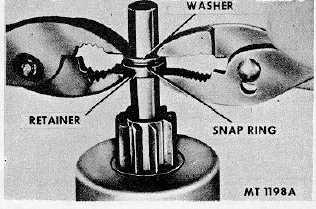

c.

To force the retainer over the snap ring, place

a suitable washer over the shaft and squeeze

the retainer and washer together with pliers,

Fig. 11.

d.

Remove the washer.

Fig. 11 Installation of Retainer And Thrust Collar

CTS-2258-K Page 8

PRINTED IN UNITED STATES OF AMERICA

|