|

| |

TRUCK SERVICE MANUAL

TM 5-4210-230-14&P-1

ELECTRICAL

DISASSEMBLY

If the starting motor does not perform according to

the specifications, it will be necessary to disassemble it for

further tests of the components.

1.

Disconnect the field coil connections from the

solenoid motor terminal.

2.

Remove the thru-bolts.

3.

Remove the commutator end frame and field frame

assembly.

4.

Remove the armature assembly from the drive

housing. On some models it will be necessary to

remove the solenoid and shift lever assembly from

the drive housing before removing the armature

assembly.

5.

Remove the thrust collar from the armature shaft.

6.

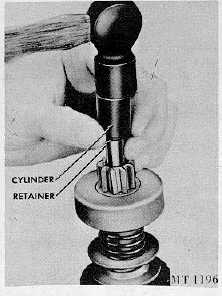

Remove the pinion from the armature by sliding a

metal cylinder onto the shaft; with a hammer striking

the metal cylinder against the retainer, drive the

retainer toward the armature core and off the snap

ring, Fig. 7.

Fig. 7 Removing Retainer from Snap Ring

7.

Remove the snap ring from the groove in the

armature shaft.

8.

Roll type clutches are designed to be services as a

complete unit; therefore, do not disassemble. If the

condition of the clutch assembly is questionable,

replace it.

INSPECTION AND REPAIR

1.

Brushes and Brush Holders: Inspect the brushes for

wear. If they are worn down to one-half their original

length, when compared with a new brush, they

should be replaced.

Clean brush holders and be sure that the brushes will

not bind in the holders. The full length of the brush

surface should ride on the commutator with the

proper spring tension (see specifications) to provide

a good contact. Inspect the brush leads and screws

to be sure they are tight and clean.

2.

Armature: Inspect the armature to be sure there are

no short circuits, opens, or grounds.

a.

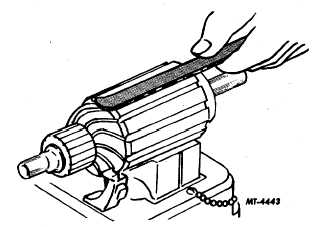

Short circuits are located by turning the

armature in a growler while holding a steel

strip on the armature. The steel strip will

vibrate on the area of the short circuit, Fig. 8.

Fig. 8 Testing Armature for Short Circuits

b.

Opens are usually found where the conductors

are joined to the commutator. Loose or poor

connections will cause arcing and burning of

the commutator. If the bars are not burned

too bad, resoled the leads in the riser bars and

turn the commutator down in a lathe. Then

under

cut

the

insulation

between

the

commutator bars 1/32".

CTS-2258-K Page 7

PRINTED IN UNITED STATES OF AMERICA

|