|

| |

TRUCK SERVICE MANUAL

TM 5-4210-230-14&P-1

ELECTRICAL

2.

Bushings should be coated with a medium grade of

engine oil.

3.

The armature shaft should be coated lightly with a

medium grade of engine oil.

4.

The drive assembly should be wiped clean.

CAUTION:

Do not clean in any degreasing tank or with

grease dissolving solvents, this will dissolve

the lubricant in the clutch mechanism.

5.

Relubricate the sprag clutch with a medium grade of

engine oil.

CAUTION:

Avoid excessive lubrication.

TROUBLE SHOOTING THE STARTING MOTOR CIRCUIT

When trouble develops in the starting motor system, and

the starter motor cranks the engine slowly or not at all, several

preliminary checks can be made to determine whether the

trouble is in the battery, starting motor, wiring circuit between

them, or elsewhere. Many conditions besides defects in the

motor can result in poor cranking performance.

To obtain full performance from a starting motor or to

determine the cause of abnormal operation, the motor should

be subjected to one or more of the following tests. Failure of

the motor to perform according to the specifications will

require removal of starter and disassembly and further checks

or adjustments made.

NOTE:

All starting motor tests should be made with

engine and battery at room temperature (not

cold).

Regardless of the construction, never operate the

starting motor more than 30 seconds at a time without

pausing to allow it to cool for at least 2 minutes. Overheating,

caused by excessive cranking, will seriously damage the

motor.

For the most part a volt-ampere tester (SE2283) will be

used in performing the starter tests and the instruction manual

supplied with the tester will provide the detailed instructions

using the volt-ampere tester.

NOTE:

All illustrations of starting motor and circuit

tests show leads connected for NEGATIVE

grounded system. Reverse the positions of

the leads when testing a POSITIVE grounded

system. Make sure the volt selector switch on

the volt-ampere tester is positioned properly

for the voltage system being inspected.

Test No. 1 -- Cranking Voltage Test

This test tells us the overall condition of battery, starter,

cables or switches to determine if sufficient voltage is

available to operate ignition system when starter is in

operation.

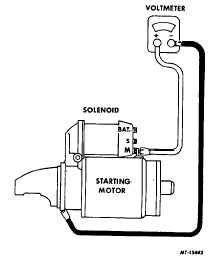

Connect voltmeter leads at the starter observing the

polarity, Fig. 2. Disconnect secondary coil lead to prevent

engine from starting. Crank engine noting voltmeter reading

(should be 9. 6 volts or better with 12-volt electrical system).

If a reading of less than 9.6 volts is found, proceed to

the next tests.

Fig. 2 Cranking Voltage Test

Test No. 2 -Battery Capacity Test

The battery capacity test is performed to determine if

the battery is in satisfactory condition. See "Battery" Section.

If the battery passes this test, continue the next test.

Test No. 3 -Voltage Drop Test

Generally, the starting or cranking circuit is a series

circuit from the battery insulated post to the starting motor

solenoid, to the motor, to ground (chassis) and return to the

battery ground post, Fig. 3.

In the cranking circuit we also have a cranking control

circuit, Fig. 3. In this circuit the solenoid is controlled or

operated by closing an ignition switch or push button starting

switch at the instrument panel. In this cranking control circuit

there

are

frequently

some

safety

switches

such

as

transmission "neutral safety switch" and/or vacuum operated

cutout switch.

CTS-2258N Page 4

PRINTED IN UNITED STATES OF AMERICA

|