|

| |

TRUCK SERVICE MANUAL

TM 5-4210-230-14&P-1

ELECTRICAL

REMOVAL

When removing the spark plugs from the engine,

certain items should be remembered:

1.

When disconnecting ignition cables from spark plugs,

do not pull on cables but grasp the cable boot and

carefully pull. To pull on cable may break the

conductor in the resistor-type cable.

2.

Observe location and routing of cables to avoid

incorrect installation. Special attention should be given

in routing spark plug cables, as cross fire (carburetor

spit-back), rough operating engine, or short plug life

will result if incorrect wire routing is encountered. If an

engine is suspected of incorrect wire routing, compare

wires with an engine which is known to be correct.

NOTE:

Cross fire is most likely to occur on a V8

engine between consecutively firing cylinders

when these cylinders are located on the same

bank.

3.

After loosening each plug about two turns, blow out any

accumulation of dirt around the base of plugs with

compressed air. This prevents debris falling into

cylinder

combustion

chambers

when

plugs

are

removed.

INSPECTION

Discussed in the following paragraphs are various instructions

pertaining to different spark plug appearances and possible

causes of their defects.

Preliminary Examination

If spark plugs in question reveal cracks, worn

electrodes or other obviously unsatisfactory conditions, they

should not be used again.

Gaskets

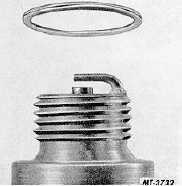

If the spark plug gaskets are not compressed, Fig. 1, it

is an indication that the plugs have not been properly

tightened to prevent blow-by between the spark plug and

cylinder head. This condition results in excessive burning of

the electrodes and overheats the insulator tip, which may

cause preignition.

If the gaskets are flattened or compressed to a point

where they have become distorted (out of round) or torn, Fig.

2, it is an indication that the spark plugs have been tightened

to the extent that damage may have been inflicted on the plug

itself.

Excessive torque will cause strain on the steel shell of

the spark plug and result in cracked insulators, distortion of

metal shell

and gap setting, as well as blow-by between the

component parts of the plug.

If the gasket is properly compressed (approximately

one-half of the original thickness) showing a flat, clean, even

surface, Fig. 3, it indicates that the spark plugs were properly

installed.

Spark Plug Appearances

Deposits normally occur in distinct bands on insulator.

The tip deposits near the electrodes are the ones which may

affect spark operation. If they become conductive, their

"shunt resistance" is said to drop, and the plug is short

circuited.

Fig. 1 Not Properly Tightened (Gasket Not

Compressed)

Fig. 2 Overtightened (Gasket Distorted)

Fig. 3 Properly Torqued

CTS-2016-J Page 3

PRINTED IN UNITED STATES OF A MERICA

|