|

| |

TM 5-4210-230-14&P-1

VEHICLE OPERATION

BRAKE RELEASE (Parking)

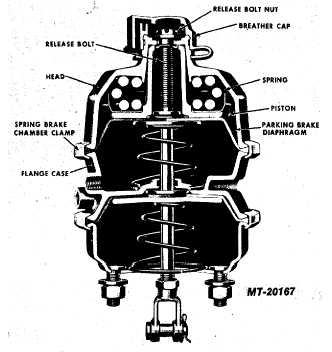

MGM SPRING BRAKE

To release the spring brake (manual release) in the

event there is loss of air and the vehicle must be towed, the

spring brake must be manually released or “caged”.

Cross Section of MGM Spring Brake Assembly

If the release bolt should bind, apply "Liquid Wrench"

or equivalent to the bolt and allow to soak into the threads.

In the event the air source has been depleted the

release bolt can be backed off by removing the breather cap

and turning the release bolt counterclockwise 57.15 to 63.5

mm (2 1/4" to 2 1/2") or approximately 30 turns. When

turning the bolt you will actually be pulling or collapsing the

spring manually.

BRAKE RESET (Anchor Lok)

Charge spring brake chambers with air pressure.

Remove the release stud and nut from the spring housing and

reinstall the access plug in the housing opening. Reinstall the

release stud and nut in the carrying pocket on the brake

chamber housing.

BRAKE RESET (MGM)

If the release bolt threads are dry apply a light coat of

"Never Seeze" lubricant or equivalent to the threads. Do not

apply "Never Seeze" lubricant supplied in an aerosol can.

To manually reset parking brake at each spring brake

chamber, screw release bolt down into unit until nut is

bottomed against the receiver. Torque nut to 67.79 N.m (50

ft.lbs.) and reinstall breather caps.

BRAKES (Hydraulic)

CAUTION

Hydraulic brake systems used on S-Series

models

are

power

assisted.

Braking

capabilities will be greatly reduced without

engine assist. DO NOT MOVE VEHICLE

WITH DEAD ENGINE.

If a failure is experienced in one side of the split

hydraulic system, the vehicle will still have the remaining

portion of the split system to allow stopping the vehicle;

however, the vehicle should be operated only with extreme

caution to reach a repair facility since the braking capabilities

will be reduced.

BRAKE PEDAL

Should the brake become wet, immediately dry them

while the vehicle is moving by light application of the brake

pedal.

PARKING BRAKE (Burnishing)

Refer to Maintenance Section.

CLUTCH PEDAL

Do not ride the clutch pedal. Keep your foot off the

clutch pedal except to shift gears or when the truck is being

brought to a stop.

DRIVING (Manual Transmission)

1.

Always check the brake system by depressing the

brake pedal before attempting to drive the vehicle. This

will familiarize you with the brake pedal action.

Observe the air gauges to determine if the minimum of

483 kPa (70 psi) pressure exists.

2.

Depress the clutch pedal.

3.

Shift the transmission into first gear position.

4.

Release the parking brake.

5.

Depress the accelerator pedal to speed up the engine

sufficiently to pick up the load. Release the clutch

pedal slowly and further depress the accelerator pedal

to prevent the engine from stalling while the vehicle

moves forward.

6.

As the speed increases, release the accelerator and at

the same time depress the clutch pedal. Then shift the

transmission to the next higher transmission gear.

Release the clutch slowly and depress the accelerator

as described above. Repeat this procedure as you shift

progressively into the higher speed ranges.

DRIVING DOWNHILL

A safety rule followed by all experienced drivers when

driving downhill, is to use the brakes and transmission gear

combinations to keep the vehicle under control. Before

entering the downhill grade, apply the brakes to

3

|