|

| |

TM 5-4210-230-14&P-1

VEHICLE OPERATION

BRAKE ANTILOCK MONITOR (Warning) LIGHT

A satisfactory antilock system is indicated each time

the ignition key switch is turned to either "ON" or "RUN"

position

with

the

antilock

warning

light

momentarily

illuminating, followed by the light going out and remaining off.

If the warning light should remain "ON" a problem is

indicated in the antilock control system. Should this condition

occur, the service brakes will function in the normal manner;

however, the vehicle will not have the added safety and

advantage of the antilock.

If the antilock warning light comes on and stays on, the

antilock system should have an "Ignition Cycle Check"

performed to determine if all or any computer modules and air

control valves are operating satisfactorily. Refer to VEHICLE

MAINTENANCE "Brake Antilock System" for Ignition Cycle

Check.

As the vehicle is driven about 24 km (15 mph) the

antilock warning light should remain "OFF". If the light should

come "ON" and remain on above 24 km (15 mph), a wheel

sensor problem may exist. Excessive spin on one drive wheel

relative to the other on some axles may cause the monitor

light to go "ON". To correct this condition, the ignition switch

must be turned "OFF" and back "ON" to reset the system and

correct the condition.

If wheel spin is not the cause of the light remaining on,

one or more of the sensors could be the problem. Refer to

VEHICLE MAINTENANCE "Brake Antilock System" for quick

trouble shooting of antilock system.

BRAKE PEDAL

When making a stop for a traffic light or going down a

long grade, do not "fan" the air brake pedal as this wastes air

pressure. On long grades, use snubbing "on-off" brake

application to reduce the possibility of extreme heat and wear

to the brake lining. A good policy to follow is to downshift

your vehicle on long grades to obtain maximum engine

assistance in reducing vehicle speed. The best way to make

a stop is to apply the brakes as hard at first as the road and

load conditions will permit and then gradually reduce the

pressure, so that at the end of the stop there is sufficient air

pressure to hold the vehicle.

BRAKES PARKING

If both air systems fail or are depleted the spring

brakes apply.

To release, repair air leak and recharge system to 483

kPa (70 psi). If leak cannot be repaired and the vehicle must

be moved, the spring brake must be manually released.

CAUTION

To avoid personal injury or property damage

when manually releasing the spring brakes,

be sure to block the wheels so that vehicle

cannot move when the brakes are released.

For

towing,

make

sure

the

vehicle

is

connected or secured to tow vehicle before

releasing the spring brakes.

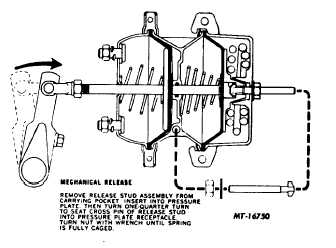

BRAKE RELEASE (Parking)

ANCHOR LOK SPRING BRAKE

In the event it is necessary to move the vehicle after an

emergency application (before air pressure can be restored),

the

emergency

parking

spring

can

be

compressed

mechanically to release the brake. A release stud "spring

caging tool" is furnished with the brake chamber assembly.

The release stud engages in the spring pressure plate and its

nut is tightened to compress "cage" the spring and release the

brake.

Apply a light coat of Never Seeze to the threads of the

release stud to avoid any unnecessary wear of the threads.

Remove the access plug from the end of the spring chamber.

Insert the release stud through the opening in the chamber

and into the spring pressure plate.

Turn the release stud 1/4 turn to engage the tangs on

the release stud into the slot in the pressure plate. Install the

nut on the release stud. Be sure tang on release stud stays

engaged with slot on pressure plate while installing the nut.

Tighten the nut with a wrench to compress the spring.

2

|