|

| |

TRUCK SERVICE MANUAL

TM 5-4210-230-14&P-1

ELECTRICAL

INTRODUCTION

Outlined below are service procedures covering lights

used on typical S-Series vehicles. Some vehicles may be

equipped with additional accessory lights which are not

covered herein.

When diagnosing light failure, first check for a

"blown" fuse or tripped circuit breaker. Fuse sizes and

locations are listed in the circuit diagram section of the Truck

Service Manual Refer to the appropriate section covering the

model year of the vehicle being serviced. If a "blown" fuse or

tripped circuit breaker is found, inspect wiring circuit for cause

of overload and make necessary repairs.

If fuse or circuit breaker is satisfactory, check for

"burned out" light bulb and replace if necessary. Light bulb

types used in various lights are listed in the LIGHT BULB

CHART in this section.

If light bulb is good, check wiring and connectors for

an "open" circuit. A 12-volt test light can be used to check

circuit continuity. Refer to the appropriate wiring circuit

diagram.

HEADLIGHTS

HEADLIGHT AIMING

Various types of headlight aiming equipment are

available commercially. When using aiming equipment,

follow instructions provided by the equipment manufacturer.

Where headlight aiming equipment is not available,

headlight aiming can be checked by projecting the upper

beam of each light upon a screen or chart at a distance of

about 25 feet ahead of the headlights. The truck should be

exactly perpendicular to the chart.

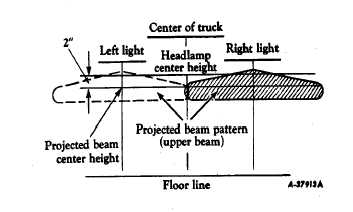

Fig. 1 Headlight Aiming Pattern

The vertical lines on the chart (Figure 1) mark the

distance between the vertical center lines of the headlights

and are equally spaced from the center line of the chart.

A horizontal line should be placed on the chart at a

level of two (2) inches below the height of the headlight

centers above the floor.

With headlights on "HIGH" beam, the "hot spot" of

each projected beam pattern should be centered over the

point of intersection of the vertical and horizontal lines on the

chart, as shown in Figure 1.

If necessary, adjust headlights vertically and/or

laterally

to

obtain

proper

aim.

(See

HEADLIGHT

ADJUSTMENT).

IMPORTANT

Headlight aim should always be checked on a

level floor with the vehicle unloaded.

In some states, the above instructions may

conflict with existing laws and regulations.

Where this is the case, legal requirements

must be met.

Modify the instructions accordingly.

HEADLIGHT ADJUSTMENT

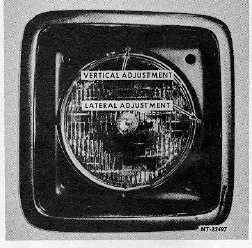

Adjusting screws are provided to move the headlight

assembly in relation to the hood (fender) to obtain correct

headlight aim.

Lateral or side-to-side adjustment is accomplished by turning

adjusting screw at side of headlight (Figure 2).

Vertical or up-and-down adjustment is accomplished by

turning adjusting screw at top of headlight (Figure 2).

Fig. 2 Headlight Adjusting Screws

CTS-2781S Page 3

PRINTED IN UNITED STATES OF AMERICA

|