|

| |

ENGINE DIVISION SERVICE MANUAL

TM 5-4210-230-14&P-1

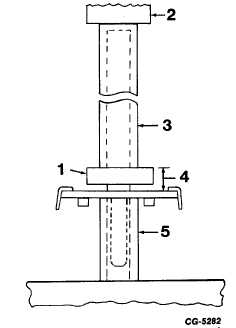

Fig. 41 Installing Tachometer Drive Bearing

1. Bearing

2. Press ram

3. Driver tool (pipe)

4. 14.3 mm (9/16 in.)

5. Support (pipe)

6.

Install new tachometer drive gear on distributor shaft.

New gear will have pin hole drilled in one side only.

Install as follows:

a.

Position gear on distributor shaft and align pin

hole with hole in shaft.

b.

Support distributor shaft in drill press and drill

hole through other side of gear.

c.

Install roll pin.

7.

Lubricate

and

install

mechanical

advance

components and trigger wheel assembly (See

Mechanical Advance System Service).

Tachometer Driven Gear and Shaft

The tachometer driven gear, shaft and bushing are

not provided for service. However, at the time of distributor

overhaul, these parts should be thoroughly cleaned and

lubricated as outlined below.

1.

Remove tachometer drive shaft cover as follows:

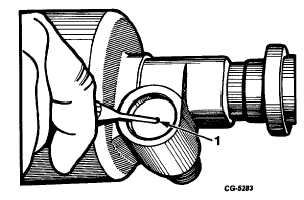

a.

Drill a 3mm (1/8 inch) hole in center of cover

(Figure 42).

b.

Insert a hooked tool or a punch into hole in

cover and pry cover from distributor housing

(Figure 42).

Fig. 42 Removing Tachometer Drive Shaft Cover

1. Drill Hole in Cover.

2.

Clean old lubricant from tachometer drive gear and

cavity in distributor housing. (See "IMPORTANT"

under Cleaning and Inspection).

3.

Inspect tachometer driven gear, shaft and bushing.

If excessive wear or damage is indicated, replace

distributor assembly.

4.

If parts are satisfactory for reuse:

a.

Fill tachometer drive gear and cavity with ball

bearing lubricant (Humble "Andok 260" or

equivalent).

b.

Install new tachometer drive shaft cover in

distributor housing.

DISTRIBUTOR REASSEMBLY

1.

Install distributor shaft into distributor housing as

outlined below:

IMPORTANT

If a new distributor shaft is being installed, a new

distributor driven gear or thrust collar and new

thrust washers must also be installed.

a.

Position new upper thrust washer(s) on shaft.

CGES-145-U Page 19

PRINTED IN UNITED STATES OF AMERICA

|