|

| |

TRUCK SERVICE MANUAL

TM 5-4210-230-14&P-1

ELECTRICAL

The coil used with the transistor ignition system has the

outward appearance of a standard coil; however, it contains

special high ratio windings that produce higher secondary

voltage at all engine speeds.

COIL SERVICE

Ignition coils do not normally require any service except

to keep all terminals and connections clean and tight. In

addition, the coil should be kept reasonably clean, but it must

not be subjected to steam cleaning or similar cleaning

methods which may cause moisture to enter the coil unless it

is of the hermetically sealed type. Rubber nipples on the high

voltage terminals are valuable in preventing "tracing" or

leakage of current across exposed surfaces.

If poor ignition performance is obtained, and the coil is

suspected of being the cause, the coil may be tested on the

truck or it may be removed for the test.

COIL TESTS

Various types of testing instruments are used in testing

ignition coils. One of these makes use of an open or

protected spark gap, while another reports the coil condition

on a meter or scope. This second type of tester is usually so

designed as to permit testing of the coil without making any

connection to the secondary terminal. This eliminates certain

variables caused by altitude, atmosphere or spark gap

electrode conditions.

The

spark

gap

tester

should

always

be

used

comparatively. That is, a coil known to be good should be

compared with the questionable coil. Both coils should be at

same temperature and identical test leads must be used.

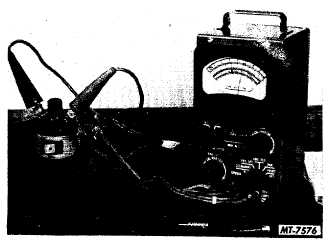

Fig. 3 Coil Tester

Before the testing instrument is used, a lamp and test

point should be applied to check coil for open or grounded

circuits. To test for an open primary circuit, put test points on

the two primary terminals. If lamp does not light, primary

circuit is open. To check secondary circuit, put one test point

in high tension terminal and the other at one of the primary

terminals. Lamp will not light, but tiny sparks will be noted

as test points are rubbed over terminals if secondary winding

is not open. If secondary is open, no sparks will occur.

Most ignition coils can be tested for grounded windings

by placing one test point on a clean part of the metal

container and touching the other point to primary and high

tension terminals. If lamp lights or tiny sparks appear at the

points of contact, windings are grounded.

NOTE: This test does not apply to secondary windings

of coils used on insulated or two: wire electrical systems,

since these coils have one end of the secondary winding

grounded to metal container. The primary winding of this type

of coil, however, may be checked for ground.

When using a meter-type coil tester to test a coil

without removing it from the vehicle, be very careful to avoid

touching tester case to truck. Many such testers have a

ground connection to the case, touching case to truck would

produce a short circuit and possible serious damage to the

equipment.

Details of the testing procedures and the manner in

which various testers are used will be found in the tester

operating instructions.

TWELVE-VOLT SYSTEM

The coil used with the 12-volt system, Fig. 4, has more

turns of wire in both the primary and secondary windings and

a higher ratio between windings than in 6-volt coils of same

size. The increased number of turns in primary winding

results in a higher inductance in this winding, which makes it

possible for coil to provide a higher secondary voltage output

throughout the speed range.

In order to improve ignition performance during

cranking, an ignition resistor is used with the 12-volt ignition

coil. This external resistor is connected in series with primary

circuit between battery and coil.

Ignition resistor is wound with wire which changes

resistance only slightly with temperature. This characteristic

prevents excessive primary current at low temperatures, and

thus reduces the tendency for distributor contact points to

oxidize during cold weather. To

CTS-2013-E Page 4

PRINTED IN UNITED STATES OF AMERICA

|