|

| |

TRUCK SERVICE MANUAL

TM 5-4210-230-14&P-1

ELECTRICAL

DESCRIPTION

The ignition coil is a pulse transformer that steps up

the low battery or alternator voltage to the high voltage

necessary to jump the gaps at the spark plugs in the engine

cylinders. This voltage may reach as much as 20, 000 volts in

some installations.

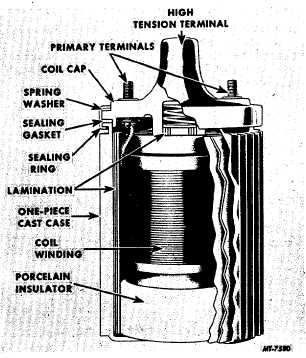

The ignition coil, Figs. 1 and 2, contains three essential

parts: a primary winding consisting of a few hundred turns of

relatively heavy wire, a secondary winding consisting of many

thousand turns of very fine wire, and laminated soft iron which

serves to concentrate the magnetic field. The primary winding

is assembled around the outside of the secondary winding,

and the laminated iron is distributed so that one portion

serves as a core for the windings and the remainder as a shell

around the entire subassembly. This subassembly is then

placed in the coil case and the remaining. space nearly filled

with insulating compound :r oil and the coil cap assembled

into place.

Fig. 1 Steel Encased Coil (Cutaway View)

IGNITION COIL TYPES

There are a variety of ignition coils for various types of

operation, with each type of coil being supplied in several

models, each designed to incorporate a specified winding to

make it suitable for operation with a particular engine under

specific operating conditions.

Fig. 1 illustrates an oil-filled and hermetically sealed

ignition coil housed in a one piece steel case. Hermetic

sealing of the ignition coil prevents the entrance of moisture,

which would ultimately cause coil failure. Moisture may enter

an unsealed coil either directly in the form of rain, snow,

washing water, steam and so forth, or through the "breathing"

action of the coil itself. Unless a coil is hermetically sealed, it

will expel air when heated and will draw in outside air when

cooled. This is the action termed "breathing", and it results in

a gradual accumulation of water in the coil interior because of

the condensation of water vapor from the incoming air. In

addition to hermetic sealing, the coils are also filled with oil to

impart high dielectric strength to the insulation, thus further

reducing the possibility of insulation breakdown and coil

failure.

Fig. 2 illustrates a heavy-duty oil-filled and hermetically

sealed ignition coil housed in a one piece diecast aluminum

case. The fins cast in the case, plus the oil filling, permit

improved heat radiation, which is a factor in efficient ignition

coil performance.

Fig. 2 Diecast Encased Heavy-Duty Coil (Cutaway View)

CTS-2013-K Page 3

PRINTED IN UNITED STATES OF AMERICA

|