|

| |

TRUCK SERVICE MANUAL

TM 5-4210-230-14&P-1

COOLING SYSTEM

general terms.

A. RADIATOR

This component is one of the most important as this is

where most of the heat of the system is dissipated. The

radiator is made up -of the following parts:

1.

Top and Bottom Tank-look for leaks, particularly where

tank is soldered to core. Vibration and pulsation from

pressure can fatigue soldered seams.

2.

Filler Neck-the sealing seat must be smooth and clean.

Cams on filler neck must not be bent or worn so as to

allow loose fitting cap. Ensure overflow tube is not

plugged.

3.

Tubes-because these are very small, they can become

clogged, or partially so, by rust and scale. The general

condition of the cooling system and operating

temperature are indications as to the cleanliness of the

tubes. Another good test is to feel the core for cold

spots.

4.

Fins-these thin metal sheets radiate or pass off the

heat picked up by the tubes.. They should be kept free

of bugs, leaves, straw and other interference to allow

free passage of air. Bent fins should be straightened

for maximum heat dissipation.

5.

Radiator Cap-(Pressure-Sealing Type). Its purpose is

to hold the cooling system under a slight pressure,

increasing the boiling point of the cooling solution and

preventing loss of the solution due to evaporation and

overflow.

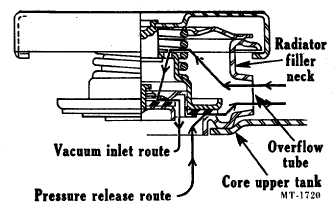

The cap (Fig. 1) has a spring-loaded valve, the seat of

which is below the overflow pipe in the filler neck. This

prevents the escape of air or liquid while the cap is in

position. When the cooling system pressure reaches a

predetermined point, the cap valve opens and will

again close when the pressure drops below the

predetermined point.

When removing the pressure type cap from the

radiator, perform the operation in two steps. Loosen

the cap to its first notch to raise the valve from the

gasket and release the pressure through the overflow

pipe. In the first stage position of the cap it should be

possible to depress the cap approximately 3 mm

(1/8"). The depression can be adjusted

Fig. 1 Radiator Cap (Pressure Type)

by bending the prongs on the cap. Care should be

taken when bending the prongs to ensure the cap is

not too loose as this would prevent proper sealing.

Then slowly continue to turn cap counterclockwise until

you can remove it.

NOTE: When removing the cap, loosen it slowly and then pause

to allow the pressure to bleed. This will avoid possible burning

by hot water or steam.

6.

Reservoir System-(if so equipped). The reservoir

installation consists of a simple, plastic reservoir

mounted near the radiator cap, coolant lines and a

special radiator cap (Fig. 2). Once the radiator cap is

installed, it should not be removed except when the

cooling system is cold and for refilling after the entire

system is drained. With this system, coolant make-up

originates from the reservoir. Coolant overflowing

from the radiator enters the reservoir to be conserved

until drawn back into the cooling system (engine and

radiator) when it cools down. The reservoir installation

provides a means of removing air from the cooling

system and keeping the coolant level at a maximum fill

condition.

The following illustrations explain the operation of this

system under conditions that exist in the cooling system.

Fig. 3: Initial condition of the system. The reservoir is

filled to the "FULL" line. The radiator has been filled to the filler

neck. Engine has started and as system begins to warm up,

expanding air in the system is expelled through the open

vacuum valve and out the radiator overflow tube into the

reservoir where it escapes at the reservoir overflow outlet.

CTS-2019P Page 5

PRINTED IN UNITED STATES OF AMERICA

|