|

| |

TRUCK SERVICE MANUAL

TM 5-4210-230-14&P-1

BRAKES-HYDRAULIC

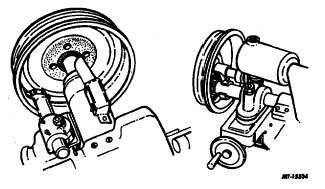

To recondition a brake drum in a lathe (Fig. 7), the

drum must be mounted so that it is centered. Use proper size

cone to provide accurate centering. Turn drum, taking only

light cuts and remove just enough material to clean up drum.

Then grind the finished surface if grinder is available or use

emery cloth on a straight piece of wood and polish the drum

friction surface.

Fig. 7 Reconditioning Drum on Brake Drum Lathe

Brake drums should be cleaned thoroughly with a

steam cleaner or hot water. Do not use a solvent which

leaves an oily residue. If inspection shows the drums may be

used without remachining, rub friction surface with fine emery

cloth or sandpaper to remove any foreign deposits. If drum

has been reconditioned, clean friction surface with fine emery

cloth or sandpaper and wash. Next examine very carefully to

see that no metal chips remain in drum.

INSPECTION OF SHOES

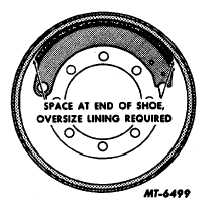

Figure 8 Defects to be looked for on Brake Shoe

When brake linings or blocks are worn to within .8

mm (1/32") on light duty vehicles or 1.6 mm (1/16") on

medium and heavy duty trucks of rivets, the brake shoes must

be removed and relined. It is recommended that all the

brakes be relined at the same time since this will maintain

balanced braking on the vehicle. If complete replacement is

not desirable or necessary, be sure that all lining on one axle

(both sides) is replaced at the same time.

Examine shoes carefully and discard those which

have any defects as shown in Fig. 8.

REPLACING LINING ON SHOES

When removing worn lining from shoes, drill out old

rivets if possible to prevent distorting shoe table. After the old

linings are removed from the shoes, the shoes should be

cleaned and buffed to remove all dirt and grease. Grease is

one of the greatest deteriorating agents of lining.

Discard used lock washers after removing lining

bolts. Use new washers when installing new lining. Replace

bolts and nuts if signs of distortion or wear are present.

Do not handle new brake linings or relined shoes with

greasy hands or allow linings to come in contact with mineral

oil or grease.

Care should be used in selecting the correct

thickness of lining for each brake shoe and drum. Usually the

standard thickness will be used. If the drum has been turned

or become worn, increasing the diameter, oversize lining may

be required.

Fig 9 Lining Selected too thin

CTS-2779 Page 5

PRINTED IN UNITED STATES OF AMERICA

|