|

| |

TRUCK SERVICE MANUAL

TM 5-4210-230-14&P-1

BRAKES-HYDRAULIC

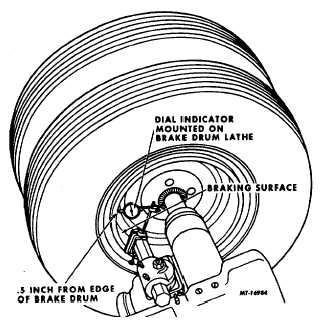

Fig 5 Checking Drum Runout on Brake Drum Lathe

REFINISHING BRAKE DRUMS

On brake drums manufactured after January 1, 1971, the

maximum diameter to which drum can be worn is stamped or

cast into drum. Drum should be discarded if worn beyond this

limit.

Minor scores on brake drum can be removed with

fine emery cloth or steel wool, but always clean emery or steel

wool particles from drum after this operation. More heavily

damaged or out-of-round drums should be ground or turned

on brake drum lathe.

If depth of scoring, bellmouth or barrel shaping

exceeds .13 mm (.005 in.), measured with micrometer across

part or all of brake surface, drum should be refinished.

Reboring or remachining limits must not be exceeded and no

heat checks, cracks or bluing is evident.

Use a micrometer also to check for an out of-round

drum. Make check by measuring drum brake surface

diameter at various points, 45 apart around circumference.

Eccentricity (out of-round) should not exceed .25 mm (.010

in.) on diameter.

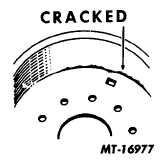

Remember that each time brake drums are turned,

less metal remains to absorb the heat developed by braking

action. Brake drums containing less metal will operate at a

higher temperature. As a result, brake fade, slow recovery

and erratic wear will be more noticeable. Also, extremely high

temperatures shorten lining life and cause heat checks and

cracks (Fig. 6) to form on inner surface of drums. These

conditions will become progressively worse until drums fail.

Fig 6 Cracked Drum

REMACHINING DRUMS

Brake drums that are otherwise in good condition can

be turned in a lathe. However, it must be remembered that

the recommended remachining or rebore limit for brake drums

355 mm (14 in.) diameter and under must not exceed 1.52

mm (.060 in.) diameter (total cut) and discarded at 2.29 mm

(.090 in.) over original diameter.

Brake drums with a diameter over 355 mm (14") may

not be increased more than 2.03 mm (.080") diameter (total

cut) and discarded at 3.05 mm (.120") over normal diameter.

These dimensions hold true for both drums, which

have maximum diameter identification, as well as drums

which are not.

IMPORTANT

The dimension located on the drum is the

discard dimension. Never remachine drums

to maximum wear or discard diameter.

There are some drums which appear to have an

exception to this; however, this is not true.

Example:

Original Diameter 11 1/32 or 11.030 inch

Maximum remachining limit 11.090 inch

Maximum wear or discard limit 11.120 inch

While an 11 inch diameter drum would be:

Original diameter

11.000 inch

Maximum Remachine Limit

11.060 inch

Maximum Wear or Discard

Limit

11.090 inch

CTS-2779 Page 4

PRINTED IN UNITED STATES OF AMERICA

|