|

| |

TRUCK SERVICE MANUAL

TM 5-4210-230-14&P-1

on floor jacks. Brake drag is checked by "feel", rotating the

drum in the direction of forward rotation as adjustment is

made.

Be sure the wheel bearings are properly adjusted (refer to

WHEELS, RIMS, TIRES Section, CTS-2032) and with brake

drums cool.

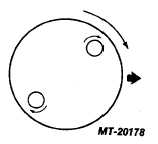

Adjust each shoe in turn by rotating adjuster cam stud

and drum in forward direction of drum rotation until a light

drag is noticeable (Fig. 4). Do not apply excessive force on

stud -13.6 Nm (120 in. lbs.) maximum. Back off adjuster

stud slightly (approximately 6 to 12 degrees). Drum should

turn freely.

Repeat procedure on opposite cam stud.

Perform same operation on brake group on opposite side

of vehicle.

BRAKE SHOE REMOVAL

Refer to Fig. 1 for numbers in parenthesis.

1.

Position vehicle on floor stands so that the wheels

are free to turn.

2.

Remove wheel hub and drum assemblies.

3.

Secure pistons in wheel cylinders with cylinder

clamps.

4.

Remove brake shoe retracting springs.

5.

Remove each shoe hold-down "C" washer (12) and

washer (11).

6.

Pull shoes free from adjuster cams and then rotate

shoe from brake group freeing ends of wheel

cylinders.

If wheel cylinder connector tubes (21) are removed, mark

wheel cylinder ports to which tubes are attached to avoid error

in re-assembly. Difficulty will be encountered in bleeding

operation if tubes are assembled in wrong location.

Fig. 4 Brake Adjustment

CLEANING AND INSPECTION

Thoroughly clean all parts (except drums) free of dirt and

grease with cleaning solvent and wipe dry.

Because studies have indicated that exposure , to

excessive amounts of asbestos dust may be a potential health

hazard, OSHA has set maximum limits of levels of airborne

asbestos dust to which workers may be exposed. Since most

automotive friction materials normally contain a sizable

amount of asbestos, it is important that people who handle

brake linings be aware of the problem and know the

precautions to be taken.

OSHA standards should be consulted with respect to

mandatory requirements as well as for suggested procedures

to minimize exposure.

DRUMS, BRAKE SHOES AND LINING

For complete details pertaining to reconditioning drums

and shoes, refer to CTS-2779.

WHEEL CYLINDERS

Inspect wheel cylinders for signs of fluid leakage or

deteriorated rubber dust boots. If brake fluid is leaking out of

wheel cylinders, replace or recondition wheel cylinders.

Some brake groups have wheel cylinder piston stops and

the wheel cylinder must be removed for reconditioning.

The two wheel cylinders mounted on one brake are

identical; HOWEVER, CYLINDERS FOR LEFT OR RIGHT

HAND BRAKES HAVE OPPOSITE CASTINGS.

Clean mating surfaces of cylinders and backing plate

before assembly to insure proper alignment.

RETRACTING SPRINGS

Inspect retracting spring for distortion such as nicks,

twisted shanks or spread of coils. Damaged spring must be

replaced.

ADJUSTING CAM AND SHOE GUIDE STUDS

Adjustment cam and shoe guide studs are equipped with

friction springs. They should easily turn with a wrench, but

should not be loose. If frozen, lubricate with penetrating oil

and work free.

CTS-2078T - Page 4

PRINTED IN UNITED STATES OF AMERICA

|