|

| |

TRUCK SERVICE MANUAL

TM 5-4210-230-14&P-1

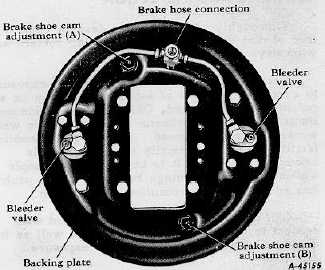

Fig. 2 External View

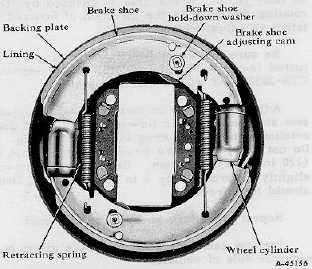

DESCRIPTION

These self-centering type brakes have two single end

wheel cylinders, each operating a forward acting shoe

providing directional braking response. The closed end of the

wheel cylinder has a slotted ramp which is the self-centering

sliding anchor for the opposite shoe. The two wheel cylinder

pistons apply equal amounts of hydraulic force to each shoe

toe.

Shoes are adjustable manually by means of two hex head

friction spring locked studs, exposed on the backing plate

(Fig. 2). Each stud rotates an adjuster cam located under a

brake shoe table. Shoe hold-downs consist of two plain

washers, multi-rattle wave washer between and a C-clip fitted

over the extended shank of the cam stud. Two retracting

springs are hooked between the shoes and have their longer

shanks connected to the anchor end of the shoes.

Upon brake application, the wheel cylinder pistons

transmit pressure to the toes of the shoes, forcing the shoe

linings into contact with the brake drum. If the vehicle is

moving forward, the drag of the drum against the shoe lining

produces "self-energization" which tends to help rotate the

shoes outwardly about their anchor points. This action

multiplies the forces exerted against the drum and produces

additional braking effect. Both shoes are forward acting

(primary shoes), self-energizing in the forward direction of

drum rotation.

If the vehicle is moving backward, the drag of the drum

on the linings is in the opposite direction and produces "de-

energization" which tends to move the shoe heels away from

their anchor blocks. Piston forces at the shoe toes are large

Fig. 3 Internal View

enough to overcome this action, but the shoes tend to rotate

inwardly about their anchor points and attempt to leave the

drum. Both shoes are reverse acting since neither is self-

energized in the reverse direction of drum rotation.

Cylinder anchor block sides are aligned on the axle

radius. As the shoes roll upon their anchor blocks to contact

the drum, the heels may also slide radially upon the anchor

block surface. The shoes thus automatically "selfcenter" in

relation to the drum.

The self-energization factor causes this brake to be

approximately three times as effective during forward

operation as it is during reverse operation; therefore its use is

generally confined to the front axle of vehicles in conjunction

with a rear axle brake of a type providing effective stopping

ability in reverse as well as forward motion.

LINING CLEARANCE ADJUSTMENT

Lining to drum clearance adjustment is required when

shoes are relined and, on occasion, to compensate for normal

lining wear. Clearance should be sufficient to avoid "brake

drag" and yet close to afford a good "pedal reserve".

Manually

operated

and

vacuum-hydraulic

actuated

brakes require adjustment (or relining) when pedal reserve

approximates 2"; that is, when the brake pedal drops to within

2" of floor board on hard application.

Adjustment is made with the vehicle resting

CTS-2078T - Page 3

PRINTED IN UNITED STATES OF AMERICA

|