|

| |

TRUCK SERVICE MANUAL

TM 5-4210-230-14&P-1

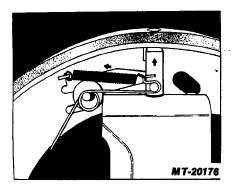

Fig. 7

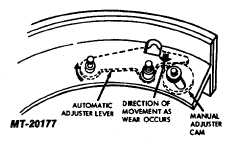

When installing shoe on hold-down, free end

of adjuster lever should bear against manual

adjuster cam which should be fully backed off

to position shown in Fig. 8.

Fig. 8

9.

Install flat washers and hold-down "C" washers.

10.

Install brake shoe return springs.

11.

Remove wheel cylinder clamps.

12.

Back off manual adjustment cams.

13.

Center each shoe before installing drum by sliding

shoe up or down in its anchor slot until the leading

and trailing edges of linings are equal distances from

the rolled edge of brake backing plate. 14. Repack

wheel bearings (refer to LUBRICATION, CTS-2412).

15.

Reinstall wheel bearings, new seals and install hub

and drum assembly. Adjust wheel bearings. Refer

to WHEELS, RIMS and TIRES Section (CTS-2032)

for proper instructions pertaining to repacking

bearings and bearing adjustment.

16.

Adjust brakes by performing the initial manual

adjustment,

referring

to

LINING

CLEARANCE

ADJUSTMENT procedure.

17.

If wheel cylinders were rebuilt or replaced the brakes

will

require

bleeding.

Refer

to

BRAKES

HYDRAULIC, General (CTS-2055 for single system

or CTS-2470 for split system).

18.

Remove floor stands from under vehicle.

LINING CLEARANCE ADJUSTMENT

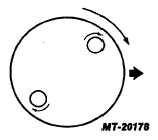

Adjust Each Shoe, in Turn: With drum installed, rotate

adjuster cam stud and drum in forward direction of drum

rotation until a light drag is noticeable (Fig. 9). Do not apply

excessive force on the stud -13.6 Nm (120 inch pounds)

maximum. Back off adjuster stud (6 to 12 degrees) until drum

turns freely. After the manual adjustment is performed, the

automatic adjusters will now maintain normal facing-to-drum

clearance.

Fig. 9

CTS-2491T Page 5

PRINTED IN UNITED STATES OF AMERICA

|