|

| |

TRUCK SERVICE MANUAL

TM 5-4210-230-14&P-1

IMPORTANT

Contact plug must be replaced when new

lining is installed. Do not use oversize

thickness lining, even though drums are

rebored.

Do

not

lubricate

adjuster

mechanism.

If new lining has no contact plug hole, cut a 19.05 mm

(3/4") hole and deburr the edges. Locate this hole by making a

proper template of the shoe table.

WHEEL CYLINDERS

Inspect wheel cylinders for signs of fluid leakage or

deteriorated rubber dust boots. If brake fluid is leaking out of

wheel cylinders, replace or recondition wheel cylinders.

Some brake groups have wheel cylinder piston stops and

the wheel cylinder must be removed for reconditioning.

RETRACTING

SPRINGS

AND

SELF-ADJUSTING

MECHANISM COMPONENTS

Inspect retracting spring for distortion such as nicks,

twisted shanks or spread of coils. Damaged spring must be

replaced.

Inspect

self-adjusting

mechanism

components

for

damage or wear, any piece of which the condition is

considered questionable must be replaced.

REINSTALL BRAKE SHOES

1.

Position wedge guide in shoe web hole on side away

from brake backing plate, with serrations facing away

from shoe table. Lay wedge with serrations matched

against guide and slot aligned over the lever pivot pin

hole shoe web (Fig. 4).

Fig. 4

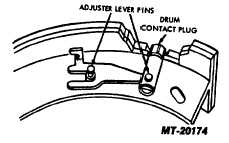

2.

Insert contact plug into the web recess and guide it

into the shoe table with plug shank over the wedge

guide and wedge. Insert adjuster lever pins through

shoe from the

opposite side and mate the actuating (center) pin with the plug

shank hole (Fig. 5).

3.

Assemble wedge washer over shoulder of pivot pin.

4.

Slide U-hook of tension spring on pin over contact

plug shank.

Fig. 5

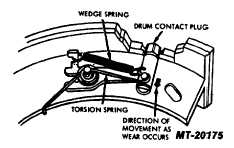

5.

Hook one end of wedge (coil) spring on the U-hook,

then install coil of torsion spring over the pivot pin

and pull free spring hook over the edge of the shoe

web. Hook free end of wedge spring over finger on

wedge (Fig. 6).

Fig. 6

6.

Press lightly upon contact plug to allow wedge to

move and fully retract the wedge against the lever

pivot pin. In this position, the plug should be even

with lining surface + 0.00 to-0.512 mm (+ 0.00 to-

0.006 inch If plug is high, clamp shoe in a vise so

that the jaws of the vice bear against the adjuster

lever (Fig. 7) and dress down the plug with a file.

Take care not to create a flat spot on the lining. An

alternate method is to dress the plug when the shoes

are ground to a true radius; however, lever must be

blocked in its extended position.

7.

Make sure that brake backing plate, wheel cylinder

anchor bolts and cylinder mounting screws are

tightened securely.

8.

Install shoes on hold-downs, locating each retracting

spring so that its long shank is hooked at the anchor

end of the shoe.

CTS-2491T Page 4

PRINTED IN UNITED STATES OF AMERICA

|