|

| |

TRUCK SERVICE MANUAL

TM 5-4210-230-14&P-1

MASTER CYLINDER

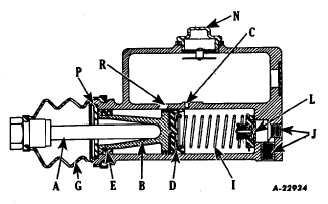

The combination or compensating type master

cylinder (Fig. 1) consists of a barrel and tank casting,

residual check valve (L), piston cup return spring (I), piston

cup (D), piston (B), piston stop (P), boot (G) and push rod (A).

Fig. 1. Typical Master Cylinder

The fluid reservoir or supply tank is cast integrally

over the master cylinder barrel. A combination filler and

breather plug (N) permits atmospheric pressure on the

reserve fluid at all times.

Depression of the pedal causes piston (B) and cup

(D) to move forward in the cylinder barrel. A very small

forward movement of cup (D) closes compensating port (C)

and the pressure stroke commences.

Minimal pressure is built up until the fluid displaced

has caused all shoes to go into contact with their drums.

Additional pressure on the pedal produces higher hydraulic

pressure within the brake system.

Removal of the operator's foot from the brake pedal

after each brake application permits the brake pedal and push

rod (A) to return independently to their off position.

The return of piston (B) and cup (D) is accomplished

by the piston return spring (I).

The piston for this type of unit is designed to carry a

primary cup (D) and a secondary cup (E). The construction of

the piston is such that

reserve fluid from the tank passes through vent (R) in a

recessed area. Thus, we have fluid on both sides of the

primary cup. The secondary cup (E) is merely a seal to

prevent loss of reserve fluid into boot (G).

The primary compensating function is to maintain a

constant volume of fluid in the system at all times, regardless

of expansion (heat) or contraction (cold). The secondary

compensating function is the replacement of additional fluid

into the system to counterbalance any loss due to gravity

seepage.

The return of piston (B) and cup (D) can be faster in

displaced volume than the return of the fluid through fitting (J)

into the master cylinder. A momentary vacuum is created in

the cylinder barrel and additional fluid is drawn into the

system through the drilled holes in piston (B) and past the lip

of cup (D). The operating fluid returns more slowly from the

wheel cylinders and lines back into the master cylinder barrel.

Any excess is bypassed by port (C) into the reservoir. Thus,

we have a cylinder full of fluid for the next brake application.

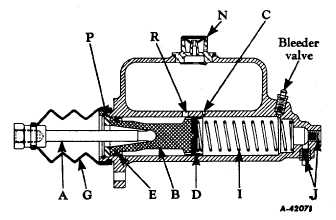

Fig. 2 illustrates a master cylinder equipped with a

bleeder valve located in the cylinder barrel. This bleeder valve

is commonly used in the larger stroke master cylinders. Its

purpose is for expelling any air that may be trapped in the

upper head end of the cylinder barrel.

Fig. 2. Typical Master Cylinder with Bleeder Valve

CTS-2055S Chapter II Page 3

PRINTED IN UNITED STATES OF AMERICA

|