|

| |

TRUCK SERVICE MANUAL

TM 5-4210-230-14&P-1

BODIES AND CABS

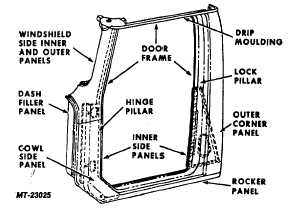

Fig. 36. Components of Side Panel Assembly

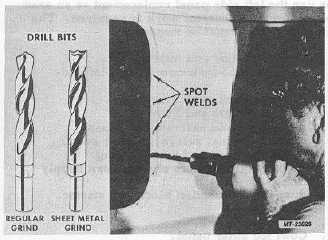

REMOVING SPOT WELDS

The actual side panel removal requires the drilling out of

spot welds which attach the side panel to other panels of the

cab. Sheet metal drill bits should be used. These are drill

bits, the ends of which have been ground for this special

purpose. An example of a sheet metal drill bit as compared to

a regular drill bit is shown in Fig. 37. When spot welds have

been removed, a pneumatic chisel is then used to open

seams which have been clinched together.

Fig. 37. Removing Cab Inner Corner Panel

SIDE PANEL REMOVAL

1.

For access to back panel joint, remove cab inner

corner panel. Remove trim strip between corner

panel and inner roof panel and drill out spot welds

(Fig. 37) around panel. Separate corner panel from

back panel, inner roof panel and side panel

assembly.

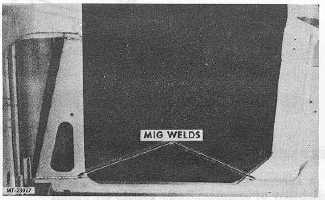

2.

Separate inside panel of side panel assembly from

sill side inner panel. Free inside panel of side panel

assembly by cutting through MIG weld (Fig. 38) at

bottom of panel. (On 80" wide cabs remove spot

weld used at cowl side inner panel).

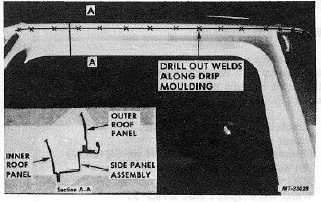

3.

Drill out spot welds along drip moulding from front to

rear and around corner to end of side panel.

Separate side panel from outer roof panel (Fig. 39).

Fig. 38. Location of MIG Weld Seams

Fig. 39. Side Panel to Outer Roof Panel Spot Welds

CTS-2714R Page 24

PRINTED IN UNITED STATES OF AMERICA

|