|

| |

TRUCK SERVICE MANUAL

TM 5-4210-230-14&P-1

BODIES AND CABS

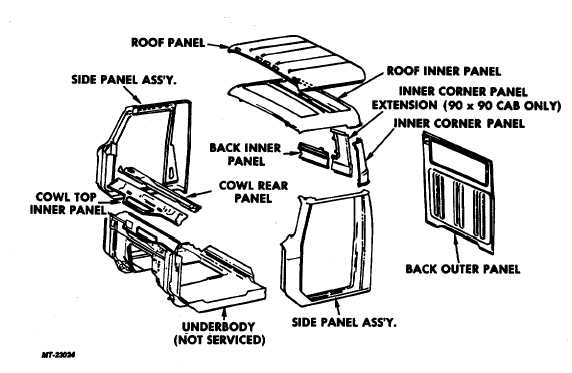

Fig. 35. S-Series Cab Panels

SHEET METAL REPAIRS

A special feature of the S-Series Cab is the availability of

complete body panels for repairing the cab. The types of

panels available are shown in Fig. 35. These panels enable a

service man to restore a damaged cab to new condition

without the usual problems associated with cab rebuilding.

Extensive metal refinishing is not required and most

restoration welds are in areas of low stress.

SHEET METAL TOOLS

To perform the necessary cab sheet metal disassembly

and rebuild work, the special tools listed here should be on

hand. Most of these are common to any cab or body

rebuilding shop.

1.

Electric or pneumatic drill.

2.

Sheet metal drill bits.

3.

Pneumatic chisel (SE-2664 or SE-2129).

4.

An assortment of C-clamps.

5.

MIG welder (SE-2640).

6.

Weld wire Spec. No. E70S-3.

PREPARING CAB FOR PANEL REMOVAL

Before sheet metal repairs to cab can be started some

mechanical work must be performed. This will depend on cab

damage and which panel is being replaced. Since the side

panel (Fig. 36) or door frame is a commonly replaced panel,

let us use the left side panel replacement as an example for

what mechanical work is required. The following items must

be removed:

1.

Left door, seat and interior trim.

2.

Dash pad and instrument panel left side mounting.

3.

Roof and back panel liners.

4.

Left scuff plate and floor mat.

5.

Windshield and rear window glass.

6.

Junction boxes, relays, dimmer switch, wiring harness

and brake piping.

7.

Marker light harness and air horn supply line.

8.

Fuse block, junction block and starter solenoid.

9.

Fuel or air tanks.

10. Cowl top outer panel.

CTS-2714R Page 23

PRINTED IN UNITED STATES OF AMERICA

|