|

| |

TRUCK SERVICE MANUAL

TM 5-4210-230-14&P-1

BODIES AND CABS

Make sure control cables are properly adjusted. (See

control

cable

adjustment

instructions

outlined

elsewhere in this section. )

2.

It is most important that all refrigerant fittings and

"O" rings be lubricated with refrigeration oil to allow

the connections to seat squarely and to be tightened

evenly to the specified torque. It is nearly impossible

to attain the correct torque with a dry fitting.

Do not attempt to disconnect or reconnect refrigerant

fittings with only one wrench. Always use a back-up

wrench when loosening or tightening fittings to

prevent damage to hoses, lines or components.

When tightening refrigerant connections, use only a

torque wrench known to be accurate. It should be

noted that torque values specified in the "Torque

Chart" are for original components with fittings

manufactured from specific materials; i.e. brass,

aluminum, etc. These torque values may not be

correct for substitute components. Use only genuine

IH replacement parts.

3.

Be certain that the evaporator core temperature

control sensing bulb is properly inserted into the

evaporator core.

4.

The expansion valve refrigerant temperature sensing

tube must be securely attached to the evaporator

refrigerant outlet tube. Also, the temperature sensing

tube and expansion valve must be tightly wrapped

with insulating tape to prevent the ambient

tempeature from affecting correct sensing of the

temperature of the refrigerant leaving the evaporator.

5.

All refrigerant hose and tubing support clamps and

strap locks must be reinstalled in their original

positions.

6.

The freon compressor oil level must be maintained

as specified. (See SPECIFICATIONS and "Checking

Compressor

Oil

Level"

under

SERVICE

OPERATIONS.)

7.

Last but certainly not least is cleanliness. When

removing components of the air conditioning system,

all openings should be immediately covered or

plugged during removal and remain so until

reinstallation to prevent the entry of dirt, moisture or

other foreign material.

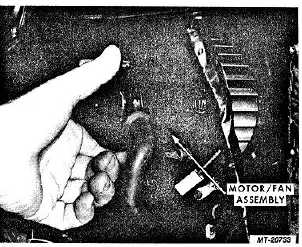

BLOWER MOTOR AND FAN

Removal:

1.

Make sure key and blower fan switches are "OFF ".

2.

Remove cover from right side of instrument panel.

3.

Remove cover from heater/evaporator unit.

4.

Disconnect blower motor wiring connector and

ground wire.

5.

Disconnect motor cooling air hose from blower

housing (where equipped).

6.

Remove mounting screws and remove motor/ fan

assembly from blower housing (Fig. 38).

7.

Remove fan from motor shaft as follows:

a.

Remove fan lock nut.

b.

Remove fan from motor shaft.

c.

Pry metal spacer from motor side of fan.

Fig. 38 Blower Motor/Fan Removal

Installation:

1.

Install fan on motor shaft as follows:

a.

Position metal spacer in shaft hole (motor

side) of fan.

b.

Position fan on motor shaft.

c.

Install fan lock nut and tighten to 1.4 to 1.7

N.m (12-15 in.lbs.).

2.

Install motor/fan assembly on blower housing and

install mounting screws.

3.

Connect motor cooling air hose to outlet on blower

housing (where equipped).

4.

Connect blower wiring connector and ground wire.

CTS-2731 Page 25

PRINTED IN UNITED STATES OF AMERICA

|