|

| |

TRUCK SERVICE MANUAL

TM 5-4210-230-14&P-1

BODIES AND CABS

The refrigerant entering the evaporator expands and

begins to vaporize. Complete vaporization requires heat. The

refrigerant absorbs heat from the air surrounding the

evaporator coils and fins. As heat is absorbed the refrigerant

vaporizes.

The blower draws warm air from the cab and

circulates it past the evaporator where the heat is absorbed by

the refrigerant. Air exhausted by the blower is cool because

the heat has been removed.

From the evaporator, the refrigerant is drawn by

suction into the compressor. This completes the refrigerant

cycle which is repeated continuously until the temperature of

the cab interior is lowered to the desired temperature.

Cab interior temperature is controlled by the

thermostatic control switch. This control is adjustable to

permit the vehicle operator to select the temperature level

desired in the cab. The blower has a multi-speed control

which permits the vehicle operator to regulate the amount of

air circulation.

OPERATION

HEATING

For proper cold weather operation the heat should be

directed toward the floor level; therefore, close all instrument

panel outlets and fully open both floor dump outlets.

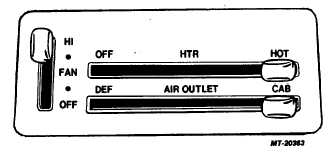

Adjust the temperature "HTR" (heat) lever as required

to give the desired degree of heat. The full right "HOT"

position provides the maximum heat. Move the "AIR

OUTLETS" control lever either to the full cab position or to

any of the other three detented positions in order to obtain the

desired air flow distribution between cab heat and defrost

requirements. For the maximum air flow, move the fan switch

to the "HI" position. The heater will also operate with the fan

motor in the "OFF" position due to the ram air introduced

during vehicle operation.

Fig. 19 Heater Controls Set for Maximum Heat

DEFROSTING

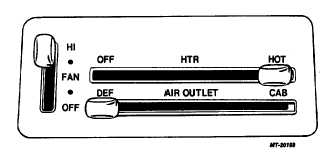

To obtain maximum defrosting, move the "HTR" lever

to the "HOT" position and place the "AIR OUTLETS" lever on

"DEF". Adjust the fan speed to provide the desired air flow.

To clear system of humid air, operate blowers for 30

seconds at "HI" speed before moving the "AIR OUTLETS"

lever to the "DEF" position. This will minimize rapid fogging of

glass, which can occur if humid air is blown onto a cool

windshield.

To improve defroster efficiency, remove ice and/or

snow from glass area.

Fig. 20 Heater Controls Set for Defrosting

FRESH AIR VENTILATION

Fresh

air

enters

the

cab

through

either

an

independent ventilation system or through the heater system

itself.

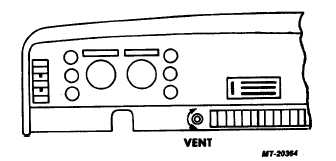

When the "VENT" knob is turned counterclockwise,

air enters the cab from the hood scoop and flows through the

instrument panel outlets and floor dumps. Except for the

ventilation mode, the knob should be rotated to its full

clockwise position (vent door closed) for all other modes of

operation.

To increase the quantity of air entering the cab in the

ventilation mode, the fan may be used to power ventilate.

Adjust the fan speed and air outlets for the desired air flow.

Fig. 21 Ventilator Control

CTS-2731 Page 13

PRINTED IN UNITED STATES OF AMERICA

|