|

| |

TRUCK SERVICE MANUAL

TM 5-4210-230-14&P-1

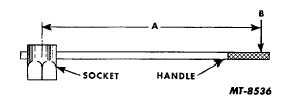

must be seated against the face of the bearing cone as shown

in Fig. 21. After the pinion bearing load is established, good

practice would be to check the ends of the bearing rollers to

see whether they are in contact with the face of the bearing

cone. Use a feeler gauge ribbon. There must be no

clearance at the ends of the rollers.

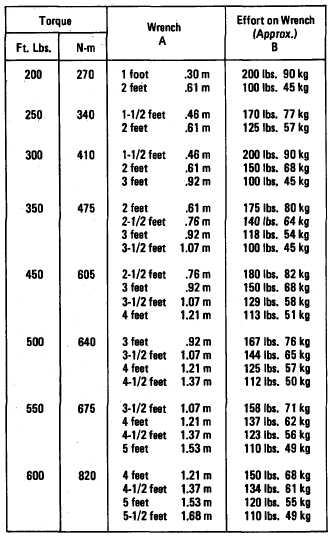

Fig. 20 Wrench Torque Chart and Diagram

Fig. 21 Roller Bearing When Correct Adjustment is Obtained.

(The rollers of the bearing must bear against the face of the

cone as shown. Rotation of the bearing during adjustment is

necessary to obtain this condition.)

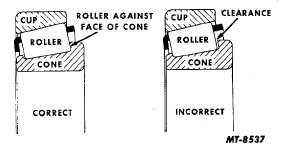

To measure the preload, wrap a strong cord or soft

wire about the pinion cage and attach end to the spring scale

as in Fig. 22. Read scale only while pinion cage is turning.

Compare this scale reading or pinion bearing preload with the

figure found in the rear axle specifications.

Fig. 22 Measuring Pinion Bearing Preload

When preload reading does not agree with the

specifications, the bearing load may be increased by installing

a thinner spacer or decreased by using a thicker spacer.

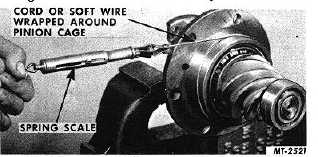

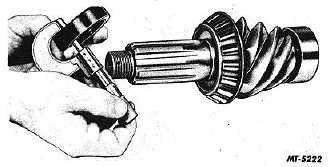

Determine spacer thickness with a micrometer, Fig. 23, and

make a new selection accordingly. Closer adjustment can be

made by working spacer to the desired thickness using emery

cloth on a flat surface. Wash spacer clean of emery cuttings

before installing on pinion

Fig. 23 Measuring Spacer Thickness

CTS-2095S-CHAPTER I-Page 10

PRINTED IN UNITED STATES OF AMERICA

|