|

| |

TRUCK SERVICE MANUAL

TM 5-4210-230-14&P-1

punch to press out remaining portion of the rivet.

NOTE

Never use chisel to cut off rivet heads or

damage to differential case might result.

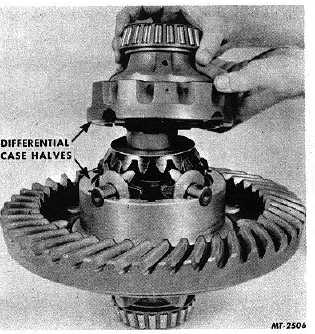

Fig. 13 Separating Differential Case Halves

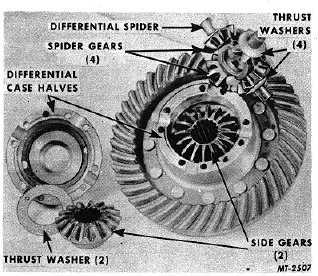

Fig. 14 Component Parts of Differential Case

5.

When reinstalling ring gear, it is suggested that

Riveting Fixture SE-2222 be used. This special tool

is designed for use with either hydraulic or

mechanical press equipment. Rivet pressures for

ring gear installation should be in accordance with

those given in the following chart.

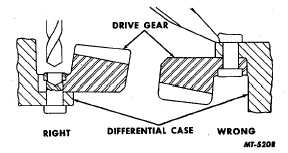

Fig. 15 Drive Gear Rivet Removal

Rivet Size

Pressure Per Rivet

Inch mm

U.S. Tons/Metric Tons

7/16

11.1125

18-20

16.3-18.1

1/2

12.7

20-25

18.1-22.7

5/8

15.8750

45-50

40.8-45.3

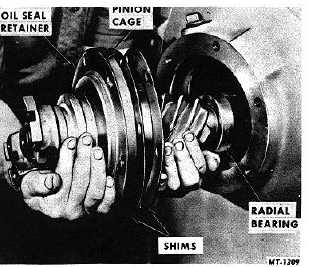

Remove Pinion and Cage from Differential Housing

There are two methods for removing the pinion and

cage assembly and the method to be used will depend on

whether puller screw holes have been provided in the pinion

cage flange or not. When no puller screw holes are provided,

removal is as follows:

1.

Remove pinion cage capscrews which hold the cage

to the differential carrier.

2.

Remove pinion and cage assembly from the

differential carrier, Fig. 16.

Fig. 16 Removing Pinion and Cage Assembly

CTS-2095S-CHAPTER I-Page 7

PRINTED IN UNITED STATES OF AMERICA

|